NPT (National Pipe Taper) pipe fittings are essential components in many industries, especially in plumbing and piping systems, for securely connecting pipes. As a leading China NPT pipe fittings factory, Jianzhi provides high-quality and reliable NPT pipe fittings that meet international standards. Knowing the size of NPT pipe fittings is important for getting the right fit, safety, and best performance in different uses. This press release looks at the key dimensions of NPT pipe fittings and why they matter in industry.

Description

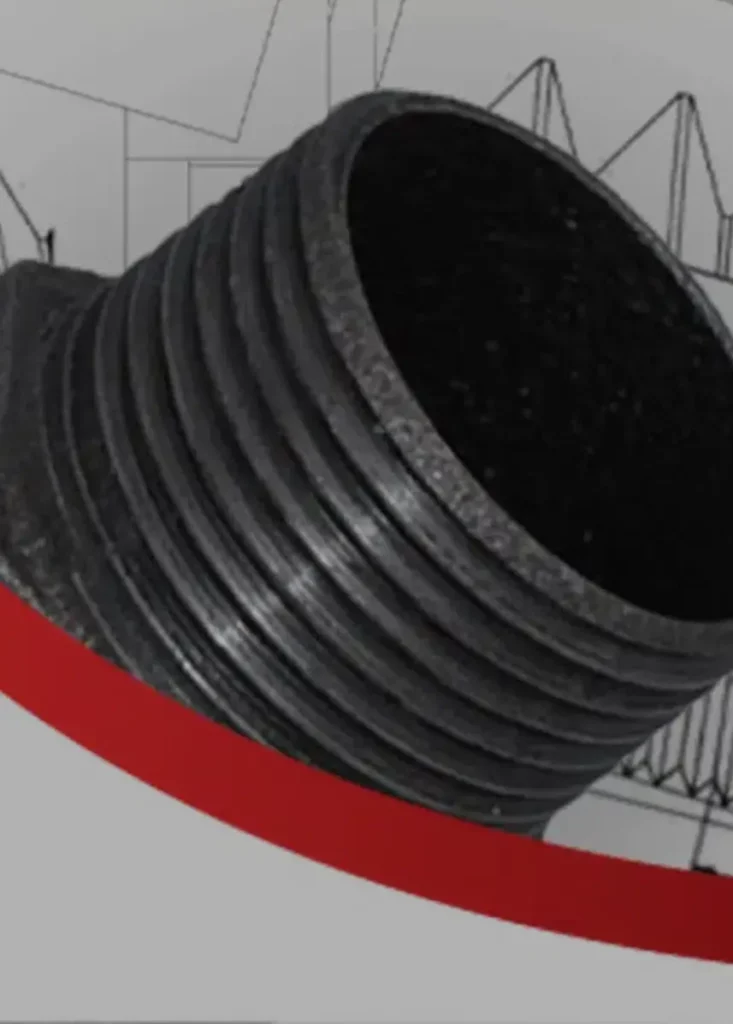

NPT pipe fittings are threaded connections used to transport liquids and gases. The term “NPT” stands for National Pipe Taper. The tapered threads create a pressure-tight seal between male and female components. These fittings are used in water supply, HVAC systems, oil and gas pipelines, and industrial equipment.

National Pipe Thread is a U.S. standard for tapered (NPT) or straight (NPS) threads used to join pipes and fittings. ANSI/ASME standard B1.20.1 covers threads of 60-degree form with flat crests and roots in sizes from ¹⁄16 inch to 24 inch Nominal Pipe Size. The taper rate for all NPT threads is ¹⁄16 (³⁄ inch per foot) measured by the change of diameter (of the pipe thread) over distance. The taper divided by a center line yields an angle 1°47′ 24″ or 1.7899°as measured from the center axis.

Commonly-used sizes are ¹⁄8, ¹⁄4, ³⁄8, ¹⁄2, ³⁄4, 1, 1 ¹⁄4, 1 ¹⁄2, and 2 inch, appearing on pipe and fittings by most U.S. suppliers. Smaller sizes than those listed are occasionally used for compressed air. Larger sizes are used less frequently because other methods of joining are more practical at 3 inches and above in most applications.

Importance of NPT Pipe Fittings Dimensions

Correct dimensions are important for NPT pipe fittings. Correctly sized fittings keep pipes connected and prevent system failures, leaks and other issues. It is important for engineers, contractors and maintenance professionals involved in piping systems to understand the dimensions of NPT pipe fittings.

Dimensions

Thread Size: The most crucial aspect of NPT fittings is the thread size, which is measured in inches. Common sizes range from 1/8 inch to 6 inches. The thread size determines the compatibility with pipes of corresponding diameters. NPT thread sizes are standardized, allowing fittings from different manufacturers to be interchangeable.

Taper Angle: NPT pipe fittings have a taper angle of 1°47′, which creates the tight, secure fit needed for effective sealing. This angle allows for a progressive tightening of the threads as the fitting is screwed into place, ensuring a leak-resistant joint.

Pitch (Threads Per Inch): The number of threads per inch (TPI) is another critical dimension. The TPI varies according to the thread size. Smaller NPT fittings, such as 1/8 inch, typically have higher TPI, while larger fittings have fewer threads per inch. This ensures the correct engagement between male and female threads.

Thread Length: The length of the threaded portion of the fitting also affects the connection’s strength and durability. A longer threaded portion allows for a more robust and secure seal.

Outer Diameter and Inner Diameter: The outer diameter (OD) and inner diameter (ID) of the fitting influence the pipe’s flow rate and pressure handling capacity. These dimensions must match the pipe’s OD and ID to ensure efficient fluid or gas flow.

About us

As one of the leading China NPT pipe fittings manufacturers, Jianzhi is committed to providing durable and precisely manufactured fittings that meet industry standards. Our NPT fittings are made from high-quality materials, including malleable cast iron and galvanized steel, ensuring long-lasting performance and resistance to corrosion and wear. Each fitting undergoes rigorous quality control checks to meet the exact specifications required by various industries.