Characteristics of gas pipelines

- The gas pipeline system is a continuous closed transportation system.

- From transmission, storage to user use, gas is under pressure.

- Due to the small specific gravity of the gas being transported, the influence of the static pressure head is much smaller than that of the liquid. When the design height difference is less than 200 meters, the static pressure head can be ignored, and the line is almost not restricted by the longitudinal terrain.

- There is no water hammer hazard in liquid pipelines.

- When an accident occurs, it is very harmful and affects a wide range. Once the pipeline ruptures, the energy released is large, the tearing length is long, and the discharged gas will easily cause a fire if there is an open flame.

Selection of pipe fittings in gas system

Pipeline classification

Gas gathering pipeline: The pipeline from the gas field wellhead device through the gas gathering station to the gas treatment plant or the starting gas compressor station, mainly used to collect the untreated natural gas extracted from the formation. Due to the high pressure of the gas well, the general gas gathering pipeline pressure is about 100 kgf/cm2 or more, and the pipe diameter is 50 to 150 mm.

Gas pipeline: from the gas processing plant or the starting point compressor station of the gas source to the gas distribution centers, large users or gas storage pipelines in major cities, as well as the pipelines connecting the gas sources, the transportation is processed to meet the pipeline transportation. Natural gas of quality standard (see pipeline gas transmission process) is the main part of the whole gas transmission system. The diameter of the gas pipeline is larger than that of the gas gathering pipeline and the gas distribution pipeline, and the largest gas pipeline diameter is 1420 mm. Natural gas is transported under pressure from the compressor stations at the starting point and along the route. The gas transmission pressure is 70-80 kgf/cm2, and the total length of the pipeline can reach thousands of kilometers.

Gas distribution pipeline: The pipeline from the urban pressure regulating and measuring station to the user branch line has low pressure, many branches, dense pipe network and small pipe diameter. In addition to the large use of pipes, the low-pressure gas distribution pipeline can also be made of plastic pipes or pipes of other materials.

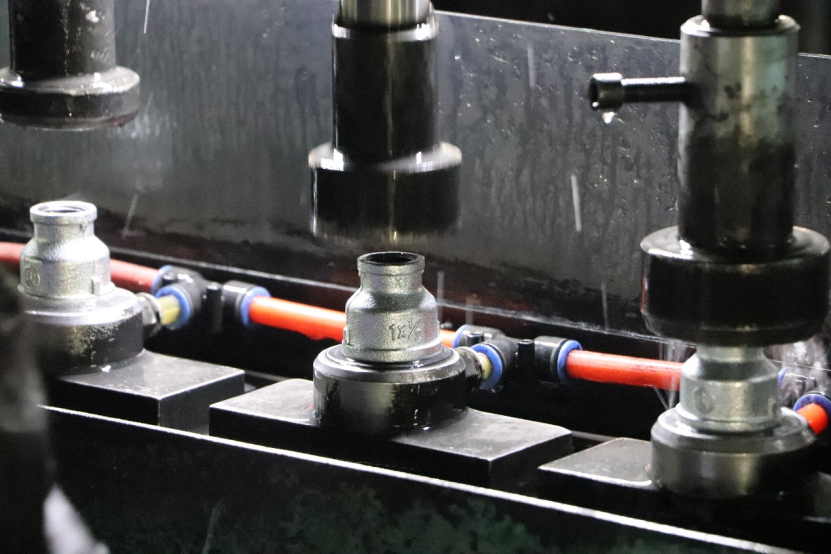

The use of malleable pipe fittings

It can be seen from the above classification of gas pipelines that malleable pipe fittings are very suitable for gas distribution pipelines. In China, a large number of malleable pipe fittings are installed in the gas pipeline system leading to thousands of households. The malleable pipe fittings here are basically made of galvanized malleable pipe fittings, and because of safety considerations, high-standard and high-quality malleable pipe fittings must be used.

Installation process of gas pipe fittings

- Operation method

- Installation preparation, be familiar with the drawings carefully, make preparations according to the construction methods determined by the construction plan and the specific measures for technical disclosure, refer to the relevant professional equipment drawings and decoration architectural drawings, and check whether the coordinates and elevations of various pipelines intersect or not. Timely research and solve with the design and relevant personnel, make a record of change negotiation, and cooperate with the civil construction to reserve holes, casings and embedded parts during the structural construction stage.

- Prefabrication: According to the design drawing, draw construction sketches such as pipeline branching, pipe diameter, reducing diameter, reserved nozzle, valve position, etc., mark the actual installation structure position, and measure the exact size of the actual installation according to the marking section. drawn on the construction sketch, and finally prefabricated according to the sketch. The feeding amount of the pipe thread at one time should not be too large. Set the adjustment dial once to increase the feeding amount and then set it again. The general requirements are: DN<25 can be set at one time. DN25-40mm should be set twice. DN ≥ 50mm is divided into three sets. The thread button should not have defects such as random thread, partial thread, burr, etc., the fracture and gap part should not exceed 10% of the whole thread, and the tightness of the thread button should be appropriate.

- Dry pipe installation

- Install the card frame and install it according to the design requirements or the specified spacing. When installing the elevator, first put the hanging rod on the steel bracket according to the slope direction and sequence, and put the lifting ring on the pipe according to the spacing position, then lift the pipe, put on the bolt and screw on the nut to fix the pipe. Install the pipe on the bracket, first place the pipe on the bracket, install the U-shaped clip on the first section of the pipe, and then install the second section of the pipe.

- Indoor pipeline installation generally should first install the introduction pipe, then install the riser, horizontal pipe, branch pipe, etc. When the indoor horizontal pipeline encounters obstacles and the straight pipe cannot pass, simmer bends or pipe fittings can be used to bypass the obstacles, such as duck neck bends, grab bends, and 45°90° elbows. When the walls of the two floors are not on the same plane, they should be laid in the form of “bend back and forth”.

- Riser installation

- Check whether the positions of the reserved holes in each layer are vertical, hanging lines, picking eyes, and planting clips. Transport the prefabricated pipes to the installation site in numbered order.

- Before installation, remove the valve cover. If there is a steel sleeve, put it on the pipe first, and install it from the first section according to the number. Apply lead oil and wrap the mahjong riser pipe to the interface and turn it into the buckle. One pipe wrench bites the pipe fitting, and the other pipe wrench twists the pipe to a moderate degree of tightness, and aligns with the requirements of the straightening mark. Leave the mouth straight and clean the hemp head.

- Check whether the elevation, direction, etc. of each reserved opening of the riser are accurate and level. Loosen the pre-planted pipe clamps, put the pipes into the clamps and tighten the bolts. Use the boom and wire drop to find the verticality from the first section, straighten the steel casing, and finally cooperate with the civil engineering to fill the holes and reserve. Temporary plugs must be added to the mouth. The installation orientation of the riser door shall be convenient for operation and repair.

- Gas risers are generally laid in the kitchen or stairwell. When the pipe diameter of the indoor riser is not more than 50mm, a union is generally installed every other floor, and the position is not less than 1.2m from the ground. When a valve is encountered, a union must be installed, and the location of the union should be set behind the valve. Unions may not be provided on pipes with a diameter > 50mm.

- Branch pipe installation

- Check whether the installation position of the gas meter and the reserved opening of the riser are accurate. Measure the size of the branch pipe and the size of the light fork bend.

- Install the branch pipe, measure the size of the branch pipe, then break the pipe, set the wire, bend and straighten the simmering lamp. Put lead oil on both ends of the lamp fork or the short tube and wrap the hemp, install the oil, and connect the gas meter to clean the hemp head.

- Use a steel ruler, a level ruler and a line drop to check the slope of the branch pipe and the size of the parallel distance from the wall, and check whether the riser and the gas meter have moved, and replace the gas meter with the branch pipe after passing the test. Carry out system pressure test and purging according to the pressure specified in the design or specification. After the purging is qualified, remove the connecting pipe and install the gas meter before delivery. After passing the acceptance procedures.

The advantages of Jianzhi Group’s gas pipe fittings

Good quality

Malleable pipe fittings used in gas systems are extremely safe because of the catastrophic consequences in the event of a leak. The malleable pipe fittings produced by Jianzhi Group, each pipe fitting will undergo a pressure test before leaving the factory, and only the pipe fittings that pass the test can be sold. In addition, Jianzhi Group also has the highest quality commitment in the industry. If you find a gray product produced by Jianzhi Group in the market, you will receive a reward of 1,618 RMB from Jianzhi Group. Therefore, there is absolutely no need to worry about quality problems when choosing the malleable pipe fittings of Jianzhi Group.

Strong supply ability

After 40 years of development, Jianzhi Group has become the largest professional malleable pipe fittings manufacturer in China. We have two super-large malleable pipe fittings manufacturing plants in Tangshan City, Hebei Province, China and Chifeng City, Inner Mongolia, which can meet the annual production capacity of 40,000 tons. supply capacity.

If you are interested in the galvanized pipe fittings produced by Jianzhi Group, please contact us for inquiry. Of course, Jianzhi Group does not only produce galvanized pipe fittings, we also provide non-galvanized black pipe fittings. Price list of black pipe fittings.

You can also click the link below to watch our YouTube channel : https://www.youtube.com/c/pipefittings

Check Black Pipe Fittings Catalog or View the Video of black pipe fittings