1 Types & Surfaces of Malleable Iron Pipe Fittings

1.1 Types of Malleable Iron Pipe Fittings From China

✅Heavy duty banded fittings

First of all, from the appearance, there is difference on the reinforcing rib. Heavy duty banded pipe fittings, the weight is much heavier, the exterior such as the first 90 degree gi elbow shown. For the mark on the fittings, heavy banded type has FM, UL marks which means this type is FM approved and UL listed. The left two types don’t have these marks.

✅Medium duty banded fittings

Fittings that are medium duty banded have the same exterior appearance as heavy duty banded, however, they are lighter in weight. All mechanical behavior complies with the Chinese Production Standard (GB). The exterior such as the second 90 degree gi elbow shown.

✅Light duty beaded fittings

Light duty beaded fittings, which are the lightest and cheapest of the three types. Even the weight is light, but all mechanical behavior conforms to the Chinese Production Standard (GB). Different types to meet the needs of different markets. The exterior such as the third 90 degree gi elbow shown.

In addition to the general models listed above, there are certain markets that require additional fittings, as shown below. Relatively speaking, the quantity is not large.

1.2 Surfaces of Malleable Iron Pipe Fittings From China

Galvanized Malleable Iron Pipe Fittings

Some customer also called it as gi fittings, galvan fittings, gmi fittings, gal fittings, hot dip galvanized fittings and electrogalvanized fittings.

Hot-dip galvanizing and electrogalvanizing are different types of surface treatment. The thickness of the zinc layer on hot-dip galvanized pipe fittings is higher than that of electro-galvanized pipe fittings. The cost of electro-galvanized pipe fittings is slightly lower than the cost of the hot-dip galvanized pipe fittings. As for the exterior surface, the electro-galvanized pipe fittings of Jianzhi Group can have the same good exterior surface as hot-dip galvanized pipe fittings. This production technology has also been granted a patent in China.

As shown in the figure below, the left is the electro-galvanized elbow, and the right is the hot-dip galvanized elbow.

Black Malleable Iron Pipe Fittings

Black iron pipe fittings, also called bmi fittings, mal fittings. The black pipe fittings are different from galvanized pipe fittings in that they have no other treatment for surface, and are mainly used in petroleum, fire protection, chilled water, and other fields. While at the same time, the price will be lower than the price of galvanized pipe fittings.

2 What Types of Threaded to Choose for Malleable Iron Pipe Fittings

Common pipe fittings threads are the following: NPT, PT, G, etc.

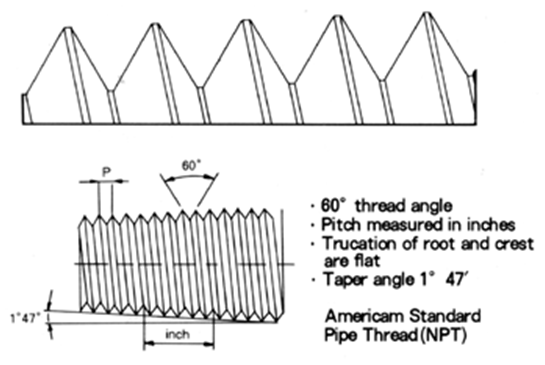

2.1 NPT Threaded

The NPT thread <National (American) Pipe Thread> is an American standard 60-degree pipe thread that is divided into general sealed cylindrical pipe threads and general sealed conical pipe threads.

1. The theoretical position of the datum plane of the conical external thread of the American general sealing thread is located in a plane perpendicular to the thread axis and at a datum distance (L1) from the small end (reference plane);

2. The basic size:

- Thread pitch diameter D2=d2=D-0.8*P

- Thread minor diameter D1=d1=D-1.6*P

3. Connect method:

There is a column/cone fit between the cylindrical internal thread and the conical external thread; a cone/cone fit between the conical internal thread and the conical external thread.

4. Tolerance

The maximum deviation of the axial position of the reference plane of the American-made general sealing tapered thread is -P~+P;

5. Thread length

The minimum effective thread length of the American general sealing tapered external thread is not less than the actual diameter of its reference distance plus the assembly allowance.

The minimum effective thread length of American-made general sealing threads is at least the deviation from the reference plane’s position plus the basic size of the reference distance plus the assembly allowance;

6. Marking

Marking of American general sealing pipe threads as follows: thread feature code, thread size code, and rotation code;

American general sealing tapered pipe thread code: NPT

American general sealing cylindrical internal thread code: NPSC

As an example, the size code is 4 and the left-handed American general tapered pipe thread is:

- The Chinese Standard is NPT 4-LH

- The US standard is 4-8NPT-LH

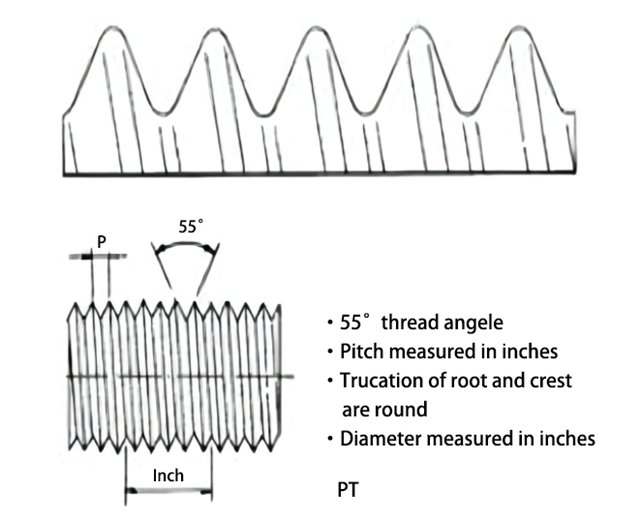

2.2 BSPT Threaded

The PT (BSPT) threaded <British Standard Pipe Thread> is the abbreviation of Pipe Thread. A pipe thread with a 55-degree sealing angle. It is a Wyeth thread. Mostly used in Europe and the Commonwealth of Nations. Usually used for water and gas pipes. Taper 1:16, For the national standard, please refer to GB/T7306-2000. Also known as ZG.

PT also stands for the Japanese and Korean inch sealing pipe thread. JIS B 0203 and KS B 0222 are the Japanese and Korean standard numbers. GB/T 7306.2 is the corresponding Chinese standard.

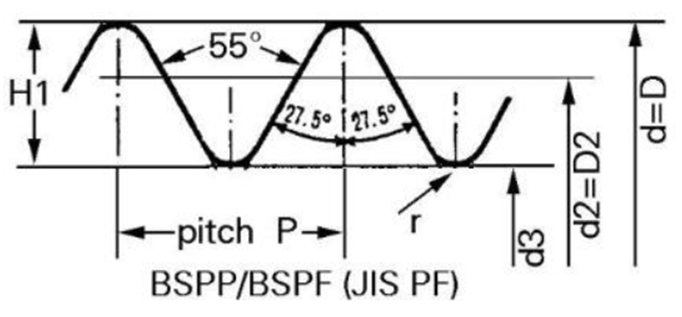

2.3 G Threaded

G is a 55 degree unsealed pipe thread, which belongs to the Whitworth thread family. “G” stands for the cylindrical thread. For the national standard, please refer to GB/T7307-2001.

The inventor of Wyeth thread, Joseph Whitworth, established his own machine tool factories while the wave of the British industrial revolution.

Various thread factories, due to the lack of a unified thread standard, manufacture threads based on their own experience, resulting in a range of sizes. The result is that it is difficult to interchange thread parts.

After changing a screw, the screw hole at the same location of the same component may not be locked.

Whitworth is aware of this serious problem as the scale of production continues to expand.

He then collected samples from different factories, measured size and shape, and collected other data. On this basis, he proposed a unified standard for thread processing, which was the origin of the Wyeth thread BSW (British Standard Whitworth) and the first thread standard in the world.

The thread profile angle in this standard is 55 degrees (BSF = British Standard Whitworth Thread Fine).

Despite the fact that Wyeth threads are no longer common in nuts and screws, they have been replaced by the unified series and the metric series.

However, BSPP (British standard pipe parallel) and BSPT (British standard pipe tape) of 1:16 are developed on this basis, and are now international standards (ISO), which are in use today.

A G is an abbreviation for gas (originating from the German Gewinde, which means “thread”), as it was initially used in a gas pipeline system.

Thread G consists of internal and external threads, which are used for non-sealing connections. The executive standard is BS EN ISO 228-1, while the old standard is BS 2779, which is no longer valid.

Well, that’s all for today. Jianzhi Group can provide various specifications and types of malleable pipe fittings, welcome your consultation.

This article is the second in a huge series of articles. In the next article, I will introduce how to find a suitable supplier of malleable pipe fittings in China, as well as the industrial layout of malleable steel pipe fittings in China. Please continue to follow us.