As a manufacturer of pipe fittings, JIANZHI are fully aware of the differences between ductile iron and malleable iron. If you would like to know too, please read on!

Malleable and ductile iron are two types of cast iron with different mechanical properties and uses.

Malleable cast iron, abbreviated as malleable iron, is the primary material of Jianzhi malleable iron pipe fittings.Malleable iron is a type of cast iron that has been heat-treated to improve its mechanical properties. It is more ductile and less brittle than other types of cast iron and can be bent, twisted, or deformed without breaking. Malleable iron is used in the production of components that require high strength, toughness, and resistance to shock and vibration, such as automotive parts, agricultural machinery, and construction equipment.

Iron History

For centuries, if not millennia, humans have used iron to construct structures. However, the majority of iron improvements are relatively recent. Until recently, “gray” and “white” cast iron were the strongest types of iron. Molten iron was molded in a cast to create cast iron equipment. This was necessary because hammering cast iron breaks it. Gray and white iron had a strong structural integrity but cracked when bent or expanded.

The first iteration that could be hammered and bent into shape was malleable iron. It was much easier to work with and less likely to fail as a result of this. However, ductile iron was invented in 1943. Strength was said to be the difference between malleable and ductile iron. This would allow ductile iron to be bent and manipulated more easily without breaking. So, which material is superior? Let’s go over their physical characteristics.

Malleable vs. Ductile Iron Properties

To compare these two materials, we will examine how well pipe fittings made of each hold up to pressure and temperature. For fittings, this is there they start expanding enough to leak, not where they physically break. These maximum pressures are for when fittings are at optimal temperatures. We will begin by looking at malleable iron fittings.

Malleable Iron Properties*

- Max Temperature:

- Class 150: 450F (232C)

- Class 300: 450F (232C)

- Max Pressure:

- Class 150: 300.23PSI (20.7bar)

- Class 300: 362.6PSI (25bar)

Ductile Iron Properties**

- Max Temperature:

- Class 150: 450F (232C)

- Class 300: 450F (232C)

- Max Pressure:

- Class 150: 275PSI (19bar)

- Class 300: 500PSI (34.5bar)

Malleable Cast Iron

Malleable Cast Iron defination

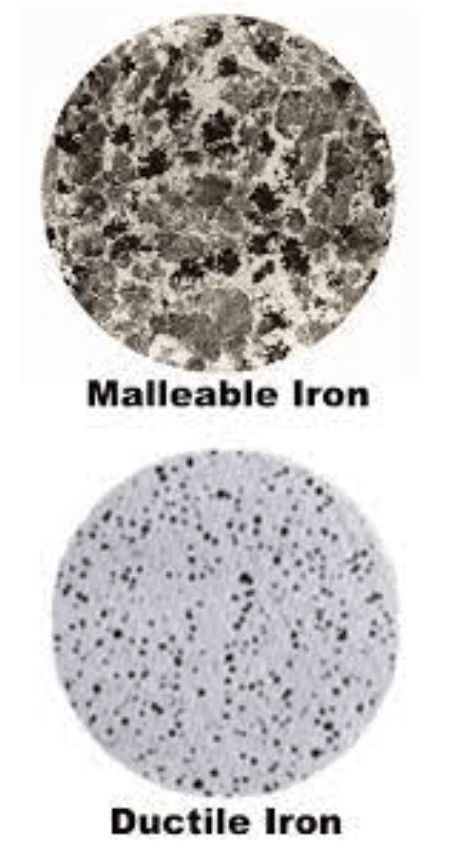

Malleable cast iron is a type of cast iron that has undergone a heat treatment process called annealing, which alters the microstructure of the material to increase its ductility and toughness. This process involves heating the cast iron to a temperature between 800-900°C for several hours, followed by cooling at a controlled rate.

The resulting malleable cast iron has a ferritic-pearlitic microstructure, which gives it improved strength, ductility, and impact resistance compared to other types of cast iron. It can be bent, twisted, or deformed without breaking, making it ideal for applications that require high strength and toughness, such as automotive parts, agricultural machinery, and construction equipment.

Malleable cast iron is also known for its good machinability, corrosion resistance, and ability to be welded or brazed. It is commonly used in the production of components that require a combination of strength, ductility, and resistance to shock and vibration.

Uses for Malleable Iron

There are two types of malleable iron: blackheart and whiteheart. Black heart malleable iron is heat-treated with an oxidizing substance, which creates a black surface layer that is more wear-resistant and brittle than whiteheart malleable iron. White heart malleable iron is heat-treated without the oxidizing substance, which results in a softer and more ductile iron.

Several general malleable cast irons

(1) Cast iron grades KTH300-06, KTH330-08, KTH350-10, KTH370-12: used to manufacture pipe fittings, low-pressure valves, rear axle housings of automobile and tractors, steering mechanisms, machine tool parts… Jianzhi malleable iron pipe fittings use KTH350-10 as the primary material.

(2) Cast iron grades KTZ450-06, KTZ550-04, KTZ650-02, KTZ700-02: manufacture castings with higher strength requirements and better wear resistance, such as gearboxes, camshafts, crankshafts, connecting rods, piston rings…

(3) Cast iron grades KTB380—04, KTB380—12, KTB400—05, KTB450—07: This is white-core malleable cast iron, which is limited to thin-walled castings and castings that do not require heat treatment after welding. Due to the complicated process, Less application in mechanical manufacturing.

Ductile iron

Ductile iron defination

Ductile iron, also known as nodular or spheroidal graphite iron, is a type of cast iron that contains small amounts of magnesium or cerium to promote the formation of spherical graphite nodules in the microstructure. This makes the iron more ductile, or easily deformed without breaking, than other types of cast iron. Ductile iron is used in a wide range of applications, including pipes, valves, pumps, and automotive components, where high strength and ductility are required.

uses of ductile iron

Ductile iron is known for its strength, durability, and ductility, which makes it ideal for use in a wide range of applications that require high strength and resistance to wear and tear. Here are some common uses of ductile iron:

- Pipe and fittings: Ductile iron is commonly used in the manufacturing of pipes and fittings for water and sewage systems, because of its corrosion resistance and durability.

- Automotive parts: Ductile iron is used in many automotive parts, including crankshafts, pistons, and suspension parts, because of its high strength and ability to withstand shock loads.

- Railway components: Ductile iron is used in the manufacturing of railway components, such as brake discs, couplers, and wheel hubs, because of its strength and wear resistance.

- Construction materials: Ductile iron is used in the manufacturing of construction materials, such as manhole covers, grates, and guardrails, because of its strength, durability, and corrosion resistance.

- Industrial machinery: Ductile iron is used in the manufacturing of industrial machinery, such as pumps, compressors, and valves, because of its high strength and resistance to wear and tear.

In summary, malleable iron is more malleable and less brittle than other types of cast iron, while ductile iron is more ductile and has a higher strength-to-weight ratio than malleable iron. The choice between malleable and ductile iron depends on the specific requirements of the application, such as the level of strength, ductility, and toughness needed, as well as the cost and availability of the materials.