Understanding the different types of pipe threads is crucial for ensuring the reliability and efficiency of plumbing and piping systems. In this article, we’ll look at the most popular pipe thread types: NPS, NPT, and NPTF. Each variety has distinct qualities and uses, making it critical to select the appropriate one for your requirements.

NPS = National Pipe Straight

NPT = National Pipe Thread

NPTF = National Pipe Thread Fuel

At Jianzhi Pipe Fittings, we pride ourselves on providing high-quality pipe fittings and comprehensive solutions for all your piping needs. As a leading manufacturer and supplier of cast iron pipe fittings and malleable iron threaded fittings, our expertise in the industry allows us to offer valuable insights into the selection and application of various pipe threads. This ensures that our customers receive the best possible products and services from Jianzhi Fittings. Whether you’re dealing with low-pressure systems or critical high-pressure applications, understanding pipe threads will help you make informed decisions and achieve optimal performance in your projects.

NPSF (National Pipe Straight Fuel) and NPT (National Pipe Taper) are two distinct threading standards used in pipe fittings, each serving different purposes. NPT features tapered threads designed for a tight seal, making it ideal for applications where leakage prevention is crucial, such as in plumbing and gas lines. In contrast, NPSF utilizes straight threads that require a gasket or sealant to achieve a leak-free connection, commonly used in fuel lines and hydraulic applications. Jianzhi, a trusted pipe fittings supplier, offers high-quality solutions that accommodate both NPT and NPSF standards, ensuring compatibility and reliability for various industrial and commercial applications. Understanding NPSF vs NPT is essential for selecting the right fittings to ensure optimal performance and safety in any piping system.

What’s the Function of NPSF, NPS, NPT & NPTF?

NPSF (National Pipe Straight Fuel) is a standard for pipe threads that features straight threads rather than tapered ones. This type of fitting is primarily designed for fuel and fluid transfer applications, where a seal is achieved through the use of gaskets or sealing compounds rather than the inherent taper of the threads.

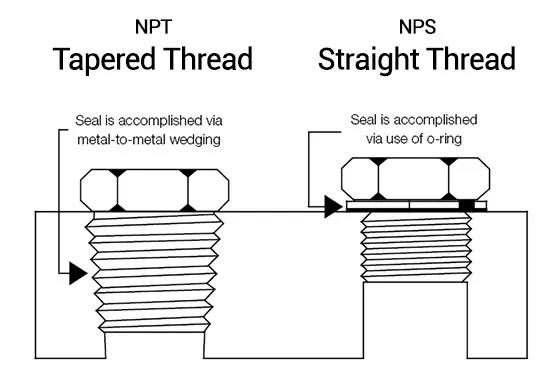

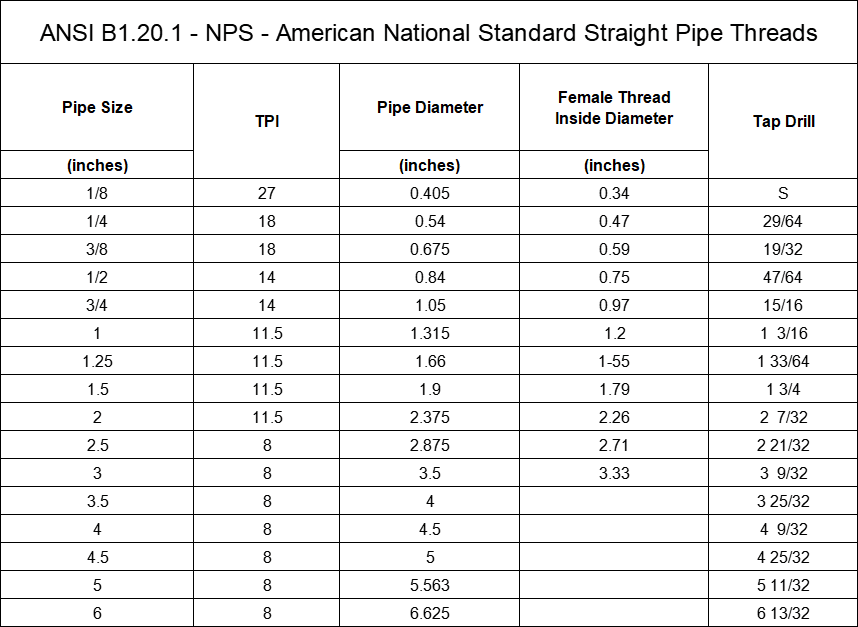

Straight threads, known as NPS (National Pipe Straight), or nps threads, are utilized in mechanical and low-pressure applications where sealing is done via gaskets or O-rings rather than the threads. This makes NPS appropriate for pipe systems with flanged connections.

NPT, or National Pipe Tapered, has tapered threads that increase or decrease in diameter along the length of the thread. This taper provides for a tighter seal as the threads tighten, making NPT excellent for high-pressure pipe systems and applications requiring a leak-proof seal, which is frequently reinforced with thread sealants such as PTFE tape.

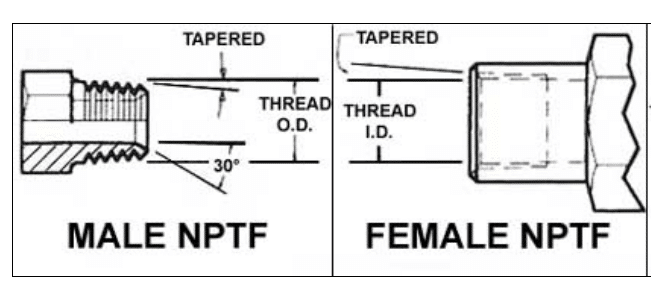

NPTF, or National Pipe Tapered Fuel, often known as crystal threads, is intended to provide a seal without the need for sealants. The threads bend slightly when tightened, resulting in a leak-proof connection appropriate for fuel systems and other applications where leaks are especially unwanted. NPTF threads are utilized for high-pressure and critical sealing applications.

Difference between NPS, NPT & NPTF?

· NPS (National Pipe Straight): NPT standard threads are straight (parallel) threads. These threads do not provide a seal on their own and are typically used in applications where the sealing is achieved using gaskets, O-rings, or other sealing mechanisms. They are commonly found in piping systems where sections are connected with flanges, making them suitable for mechanical and low-pressure applications.

· NPT (National Pipe Tapered): NPT threads are tapered, meaning the diameter gradually decreases along the length of the thread. This taper allows the threads to form a tighter seal as they are tightened. NPT threads are commonly used in high-pressure systems and applications requiring a leak-proof seal. The taper creates a mechanical seal by thread deformation, often enhanced with the use of thread sealants like PTFE tape, ensuring a secure and leak-free connection.

· NPTF (National Pipe Tapered Fuel): NPTF threads, also known as dryseal threads, are designed to create a seal without the need for additional sealants. These threads achieve a leak-proof connection by slightly deforming during tightening, providing a secure seal solely through the mechanical fit of the threads. NPTF threads are commonly used in critical and high-pressure applications, particularly in fuel systems, where leaks can be hazardous. They are ideal for applications where a reliable, sealant-free connection is required.

Main differences between NPT and NPS thread

Thread design: The main difference between NPT and NPS lies in their thread design. NPT has tapered threads, while NPS refers to straight threads.

Sealing requirements: NPT national pipe thread require the use of sealant or tape to form a tight seal, while NPS does not require it. NPS provides a threads sealant by fixing the male thread onto the gasket at the end of the female thread, providing additional safety measures in the event of gasket degradation.

Compatibility and Installation: Ensuring compatibility between NPT threaded fittings and NPS piping is crucial for proper installation. Matching threads and dimensions helps prevent leaks and ensure safe connections.

Standardization: Both NPT and NPS comply with specific standards established by organizations such as the American National Standards Institute (ANSI) to maintain consistency in piping systems.

Main differences between NPT and NPTF thread

NPTF VS NPT

The requirements for NPT (National Pipe Thread) are detailed in ANSI B1.20.1

The requirements for NPTF (National Threaded Fuel) are detailed in ANSI B1.20.3

The number of threads per inch, pitch diameter, and taper per inch of NPT and NPTF are the same. The difference lies in the large and small diameters of the thread, as well as the root and top.

The NPTF thread crest meets the parameters required by NPT, but the range is smaller than NPT.

NPTF thread roots are different from NPT thread roots. The NPTF thread root is designed to interfere with the top of the mating thread, with the aim of forming a mechanical seal through thread deformation during assembly. NPTF threads have the same basic shape, but the top and root heights have been adjusted to achieve interference fit, eliminating the spiral leakage path.

The design of the root of the NPT thread allows for clearance with the top of the mating thread during assembly.

National Pipeline Cone Fuel (NPTF), also known as the American National Standard Cone Pipe Thread Dry Seal, is defined by ASME B1.20.3 to provide a more leak free seal without the need for PTFE tape (also known as “Teflon”) or other sealants.

Although NPT, NPTF, and NPS threads may mesh and look suitable, they cannot be gentle with each other, and improper use may lead to leakage.

Why are threaded fitting standards important?

Threaded fittings must not only form mechanical joints, but also leak-proof hydraulic seals. This is achieved by matching the tapered thread form of the male thread to the thread pattern of the inner tapered thread and filling any voids between the two threads with a pipe sealant that could cause spiral leakage. The bottom of the thread is not on a cylinder, but a cone; They are gradually decreasing. The taper is 1⁄16 inches per inch, which is equivalent to 3/4 inch of a foot.

Due to the taper, the pipe thread can only be screwed into the fitting at a certain distance before it gets stuck. The standard specifies this distance as the length of the hand mesh, i.e., the distance at which the pipe thread can be screwed in by hand. It also specifies another distance – the effective thread, which is the length of the thread that forms a seal on a conventional machined pipe thread. It is more convenient for workers to know how many turns to turn by hand and how many turns to turn with a wrench, rather than these distances.

A simple rule of thumb for installing tapered pipe threads is to tighten them by hand and then rotate them one or two times with a wrench. Torque installation values can be determined by application, but standard torque specifications cannot be applied universally due to the variations involved in pipe fittings, such as the different materials of external and internal threads, the type of sealant used, and internal variations in the wall thickness of the product.

Contact us to learn more about how we can help you choose the right size fitting for the perfect leak-proof seal.