Jianzhi is a leading manufacturer specializing in NPT thread fittings and BSPT thread fittings. With advanced production technology and strict quality control, Jianzhi offers high-quality threaded fittings that meet international standards. These fittings are widely used in various industries, including plumbing, gas, and oil pipelines, providing reliable and durable solutions for different piping systems.

Depending on the location, size, and environmental factors of the pressure system, numerous types of seals are used in process industries. The type of seal used also depends on industry preferences and regional variations. Let’s discuss npt vs bspt.

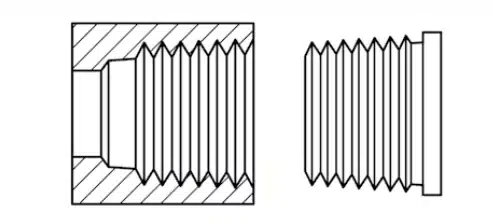

NPT Connections

William Sellers established the American standard for screws, bolts, and nuts in 1864, which later became known as the National Pipe Tapered Thread (NPT). His 60-degree thread angle, which early American clockmakers frequently employed, made the Industrial Revolution possible. Later on, these thread types evolved into the American National Standard.

Whitworth threads, with at least one thread tapered, were selected as self-sealing connection threads for pipes. This gave rise to the British Standard Pipe thread, commonly referred to as the BSP Taper or BSP Parallel thread. These days, the Whitworth thread—which is common around the world—is used to attach low carbon steel pipes.

NPT (National Pipe Thread) seals are the most widely utilized kind of seal in pressure calibration systems. A taper thread on NPT male adapters fits into the female NPT adapter. The reason they seal is because of the “out of roundness principle,” which states that the male pulls the female fitting until the connection is strong enough to withstand pressure. A problem with this design is that excessive tightening or inadequate lubrication can lead to galling and damage to the threads when connecting stainless steel to stainless steel. To seal, thread sealant is needed, but just two turns are needed. Any more than that and the seal can leak around the thread sealant.

NPT thread chart

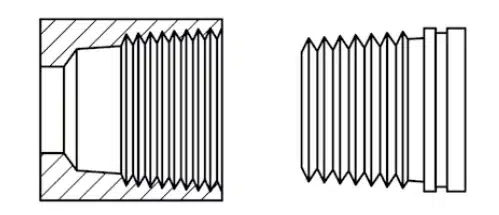

BSPT Connections

While NPT and BSPT (British Standard Pipe Taper) are comparable, there are a few key distinctions. If you cut the fitting in half lengthwise and measured the angle from root to crest to root, the angle across the flanks of the threads is 55 degrees rather than 60 degrees as it is for NPT. Another significant distinction is that the thread pitch for certain BSPT pipe sizes is different from NPT. As a result, although they will not seal, an NPT male will occasionally fit into a BSPT fitting or vice versa.

BSPT thread chart

Difference Between NPT and BSPT thread

Characteristics of NPT Threads

NPT threads are defined by the following features:

1.The taper angle is 1°47’(measured from the center axis of the NPT fitting)

2.Level peaks and troughs

3.60°angle between each crest and trough

4.At the taper’s halfway, the outer diameter of an NPT fitting is measured.

5.Pitch (the distance between threads) is measured in threads per inch (TPI)

NPT threads see much use especially in industries that are high-pressure and with temperatures also high, like petroleum and others such as chemical or water treatments. These are industries where sealing needs to be high in performance, and also strong connections are demanded, especially in piping systems that involve it. For these demands, NPT threads are preferred for handling these requirements well.

In addition, the tapered pipe shape of the NPT thread gradually reduces the gap between the pipes during the connection process, further enhancing the sealing effect, effectively preventing media leakage and ensuring the safe operation of the piping system.

In contrast to NPT threads, BSPT threads embody the British standard for 55°sealing pipe thread conical threads.

They are renowned in Europe, Commonwealth nations, and select regions of Asia for their distinctive features:

1.A tooth angle of 55°, which sets them apart from NPT threads.

2.A taper ratio of 1:16, ensuring a gradual and secure fit.

3.Excellent sealing performance, making them ideal for applications requiring tight connections.

4.Widespread usage across various industries where reliable sealing is crucial.

5.A standardized design that facilitates compatibility and interchangeability with other BSPT-compliant fittings.

NPT vs BSPT:Advantages and disadvantages

Advantages

1. Productivity of installation is high, and there is no real requirement for specialized skills for installation to happen.

2. For systems operating under low pressure, low temperatures, and without vibration issues, the leakage integrity of such setups tends to be good enough for the purposes.

Disadvantages

1.The pipe and fitting have different rates when it comes to thermal expansion. With fast temperature changes, leaks might happen because the materials react differently to the heat.

2.The bottom of the thread has a sharp notch, which causes stress to concentrate heavily there. Vibrations can lead to fatigue failure in these threaded pipe fittings due to this stress build-up over time.

Plumbing systems that can bring risks, they must avoid using threaded connections. Threads being visible, makes threaded joints weaker, meaning they might have more corrosion and can get fatigue damage quicker because of that possibility being bigger.

Jianzhi is NPT pipe fittings suppiler, offering a wide variety of

In the industry leadership position, Jianzhi Manufacturing has not only modern production equipment but also testing methods are advanced. Also, there is a technical research team, high-quality and dedicated, responsible for development. The company follows a strategy that puts market as priority, while customers are at the center of attention. It continuously launches products, which meet the demands of the market, and those needs are always considered. It is always the focus to introduce new items and develop them according to those requirements the market needs.