An NPT thread fitting is a type of pipe thread standard commonly used in North America, designed to form a tight seal for pipes and fittings in fluid and gas systems. The distinguishing feature of NPT fittings is the taper of the threads, which creates a seal as the fitting is tightened, allowing for a secure, leak-free connection. The male and female ends of NPT fittings are slightly conical, meaning they fit together tighter as they are screwed in.

NPT fittings are typically used in applications where a threaded connection is needed, such as plumbing, industrial piping, and HVAC systems. They are also widely found in the oil and gas, chemical, and manufacturing industries, where reliable connections are crucial to system integrity and safety. JianZhi NPT fittings, designed to meet stringent industry standards, are often chosen for these applications due to their precision and durability, ensuring a reliable fit even in demanding conditions.

1.Oil and Gas: NPT fittings are common in pipelines, refineries, and drilling operations where leak prevention is critical due to the flammable and hazardous nature of transported materials. JianZhi’s NPT fittings are particularly valued in this industry for their durability and high-pressure resistance.

2.Plumbing: In residential and commercial plumbing systems, NPT fittings are used for both water supply and waste drainage. Their reliable seal helps prevent leaks and maintain system integrity over time.

3.HVAC: Heating, ventilation, and air conditioning systems rely on NPT fittings to connect various components securely, such as refrigerant lines, gas pipelines, and water pipes, where a strong seal is essential to system efficiency.

4.Chemical Processing: In chemical plants, NPT fittings are used to transport chemicals, often in environments requiring high corrosion resistance. JianZhi offers fittings in materials like stainless steel and brass to withstand corrosive fluids.

5.Industrial Manufacturing: NPT fittings are frequently used in machinery and equipment to connect hydraulic and pneumatic lines. Their threaded design ensures a tight fit that can withstand the dynamic forces typical in these applications.

How does the NPT thread standard differ from other thread standards?

The NPT thread standard differs from other thread standards mainly in its thread geometry and application. NPT threads are tapered, with a taper angle of approximately 1.8 degrees, which enables the threads to compress together as they are tightened, forming a seal. This characteristic differs from other thread types, like BSP (British Standard Pipe), which typically have parallel (straight) threads and often require a gasket or O-ring to achieve a seal.

NPT fittings are also dimensioned according to specific guidelines set by American standards, such as ANSI/ASME B1.20.1, ensuring consistency across manufacturers. Other thread standards may use different dimensions, thread counts, and tapering (or lack thereof), which makes them incompatible with NPT systems without adapters.

JianZhi NPT fittings are manufactured to precise standards, making them compatible with other NPT-compliant fittings. Their commitment to quality control ensures that each fitting has the correct taper, thread angle, and dimensions, which is crucial for maintaining a leak-free connection.

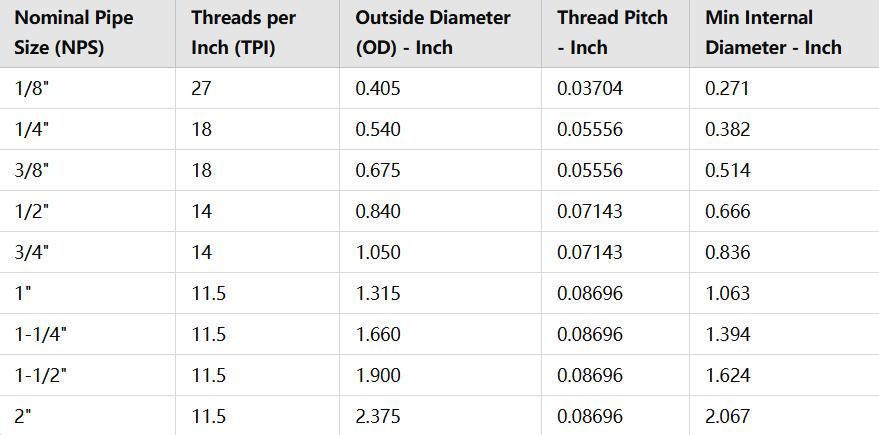

An NPT thread chart provides the standard dimensions for various sizes of NPT fittings, including the nominal pipe size (NPS), threads per inch (TPI), thread pitch, and the outside and inside diameters. NPT threads are tapered, meaning the diameter decreases slightly along the thread length. This taper helps create a secure seal when the fittings are tightened. The chart is essential for selecting the right fitting size in applications where precise fit and sealing are required, such as plumbing, gas lines, and industrial piping.

Here is a typical NPT thread chart with relevant dimensions:

Advantages

One of the key advantages of NPT pipe fittings is their resistance to corrosion, which is essential in environments where the fittings are exposed to moisture, chemicals, or varying temperatures. The corrosion-resistant nature of these fittings, particularly those made from malleable iron fittings, helps to prolong the life of the piping system, reducing the need for frequent maintenance and replacements. This durability makes NPT pipe fittings a cost-effective choice for long-term projects where reliability and minimal maintenance are critical factors. Additionally, their ability to maintain a secure and leak-free connection under challenging conditions further solidifies their importance in high-pressure systems. JianZhi Fittings ensures that all our NPT Thread Fittings are crafted to the highest standards, guaranteeing long-lasting performance.

Moreover, NPT pipe fittings are known for their ease of installation and compatibility with a wide variety of piping materials, including steel, copper, and plastic. This compatibility simplifies the integration of NPT Thread Fittings into existing systems, allowing for seamless upgrades and repairs. Whether used in new construction or retrofitting older systems, these fittings offer a dependable and robust solution that meets the demands of modern plumbing and mechanical applications. JianZhi Fittings provides a comprehensive range of NPT pipe fittings that offer a blend of strength, versatility, and longevity, making them an indispensable choice for any piping system.

Jianzhi is NPT pipe fittings suppiler, offering npt pipe fittings catalog, for example,

Leading the industry, Jianzhi Manufacturing has state-of-the-art production equipment and testing methods, as well as an excellent technical research and development team. The business continuously creates new products that meet consumer demand while adhering to its customer-centered, market-oriented attitude.