Malleable pipe fittings are generally connected by threads. In the sales process of malleable pipe fittings, the thread standard is very important. If the buyer and the seller cannot agree on the specific specifications of the threads, the malleable pipe fittings will not be able to be assembled together smoothly. Now we will review the history of thread, explore the historical origin of British standard thread and American standard thread and the development of processing technology. I hope that everyone will not confuse the threads of malleable pipe fittings during the transaction process, and buyers can also judge the quality of the threads through the processing technology.

Thread is the earliest simple machine invented by human beings and one of the most practical inventions in history. Because thread has the functions of easy assembly and detachable replacement, thread connection is widely used in all walks of life.

British Standard Thread

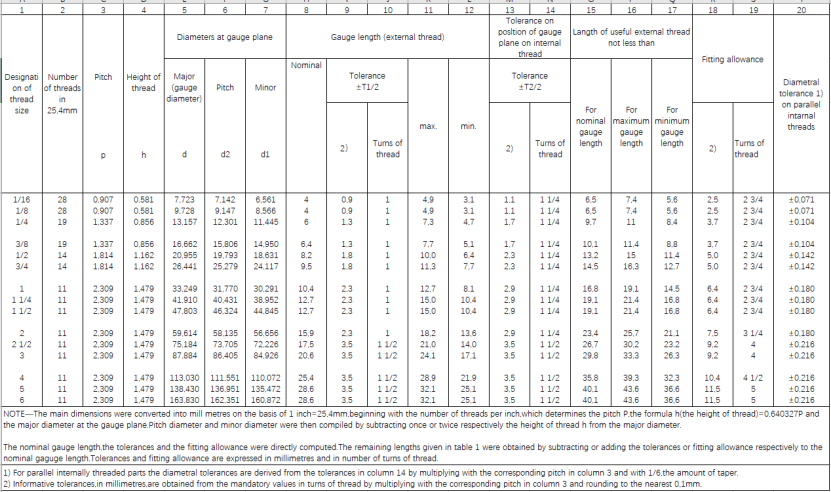

The widespread use of threads was after the first industrial revolution. The British invented screw lathes, dies and taps, which laid a technical foundation for mass production of threads. In 1841, the British Whitworth proposed the world’s first thread standard is named Whitworth thread (feature codes BSP, BSW, BSF), resulting in the thread standard technology system. In 1905, the British Taylor invented the thread gauge design principle (Taylor principle). Since then, the UK has become the first country in the world to fully master thread processing and testing technology, and the British thread standard was the first to be recognized worldwide. The imperial thread was promoted and widely used with the rise of the empire on which the sun never sets.

American standard thread

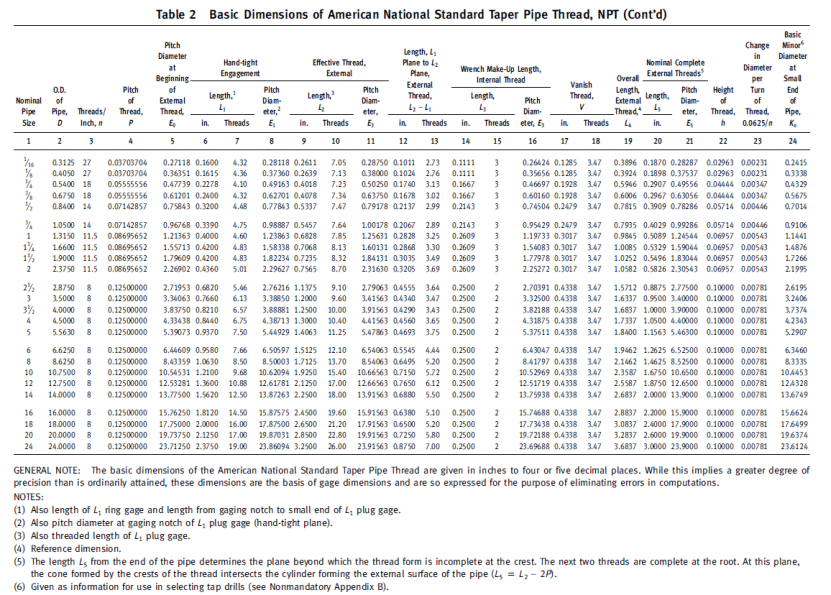

After the thread standard was promoted, the United States developed on the basis of the British Whitworth thread. After World War II, the American thread was transformed into a unified thread standard (characteristic code UN) commonly used by the Allies of World War II. The American pipe thread standard is independently developed by the Americans, and together with the British pipe thread, it constitutes the two major standards of pipe thread in the world today. American trapezoidal and serrated threads were also recognized by the Allies in World War II after World War II. American thread has an extremely important influence on thread development.

The metric common thread standard is a standard (code M) formed after the American thread, also known as the metric thread. The metric thread standard is widely used all over the world and incorporated into the ISO standard. When the metric system (the metric system is the unit of length) After being identified as an international legal unit of measurement, the status of metric common threads in international standards has been further enhanced. In recent years, more and more metric common thread standards have been promoted and applied. Metric thread standards are the development direction of future thread standards and have been widely used in China.

Thread processing method

- Thread turning

- Thread rolling

- Thread milling

- thread roll forming

The malleable pipe fittings of Jianzhi Group adopt the method of thread turning for thread processing. In the face of multi-threaded pipe fittings, Jianzhi Group adopts a method of simultaneous processing of multi-threaded pipe fittings. Ensure that the thread axis angle of the fitting meets strict requirements. The following video is the thread processing process of Jianzhi Group’s galvanized equal tee.

Jianzhi Group has been providing high-quality malleable pipe fittings products to the world, and has won the trust of customers. You are welcome to consult and look forward to reaching a close cooperative relationship with you.