Product Description

Grooved Flexible Couplings Description

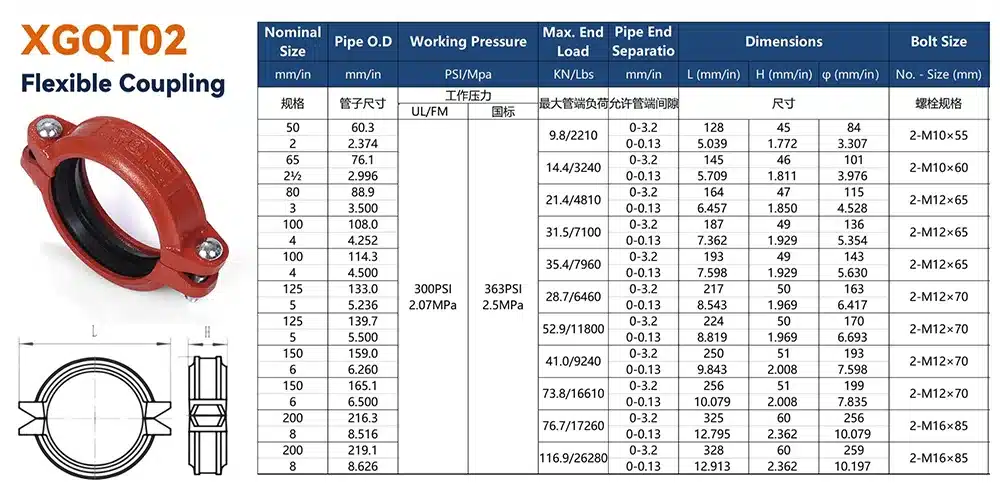

Grooved Flexible Coupling is a cutting-edge mechanical connector designed for the seamless joining of pipes across a multitude of systems, including plumbing, HVAC, fire protection, and industrial applications. This coupling stands out for its incorporation of a flexible element, typically crafted from synthetic rubber or elastomer, which enables controlled movement and effectively absorbs vibration, shock, and thermal expansion.

Key Features:

Why Choose Grooved Flexible Coupling

Grooved couplings are designed to be easily installed on pipe ends, simplifying the installation process compared to other types of couplings.These couplings are designed to flex, allowing them to accommodate a degree of misalignment, deflection, and expansion/contraction within the duct system.Using grooved flex couplings can help reduce the transmission of noise and vibration through your ductwork.Grooved flex couplings help reduce maintenance requirements and increase uptime.Easy and fast installation, which can significantly save labor costs.

Design and Functionality:

JANZHI-Malleable iron pipe fittings

EN10226 /ASMEB1.20.1/IS0228/IS07-1

Protect pipe fittings from injury during connection

disrupting their original performance

please contact our staff

0.6MPa

standard

0.5MPa

±0.3°

standard

+0.5°

363MPa

standard

330MPa

12%

standard

8%

100% individuoltesting ofthe product

Reduce carbon emissions and

use renewable energy

Focuson sustainable development

Start from 1982

Sam floot space

Tons of production per year

Tons nbentory

|

Galvanization – Threading – Detail processing – Grinding

government group

government group

Sold to over 30

countries and regions

JANZHI Group holds 13.6% market share

Gas Pipeline System holds 60% market share

customized needs of different customers

after-sales service and technical support

Customer Service