Product Description

Understanding Grooved Rigid Couplings

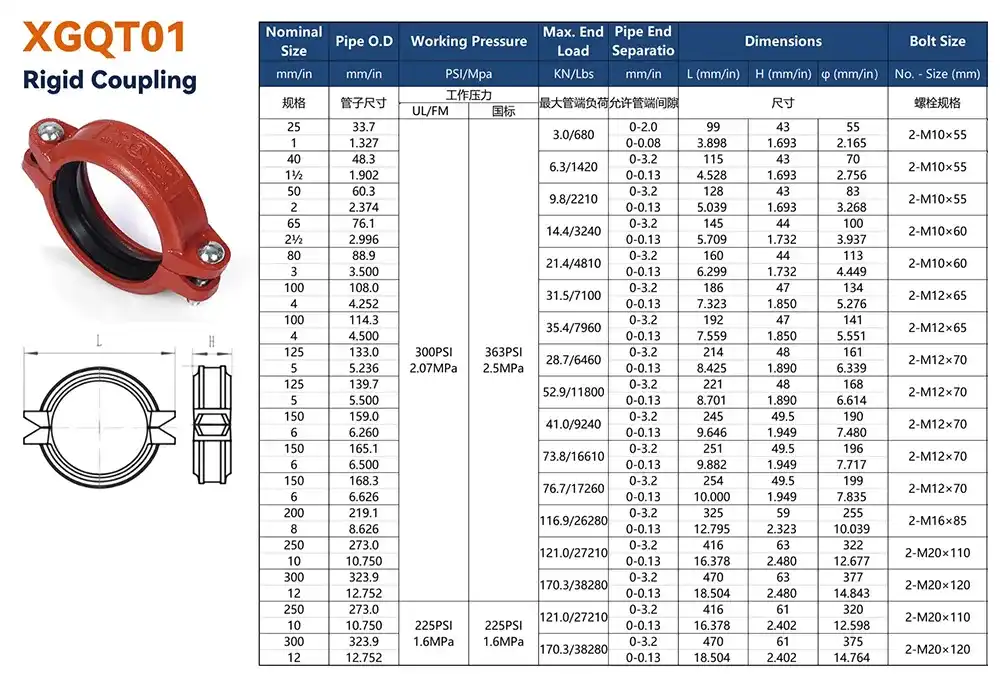

The Grooved Rigid Coupling represents a strong and dependable option for ensuring stability in pipe connections, especially in systems requiring a solid and immovable joint. Its clever design, featuring grip teeth, provides a steadfast bond comparable to age-old methods of flanging, welding, and threading. This coupling thus imparts a secure connection, pivotal for maintaining system integrity.It effectively minimizes or eliminates angular deflection, axial displacement, and rotation post-installation, making it an ideal choice for the installation of lengthy pipelines without the worry of angular deflection.

Grooved Rigid Couplings Feature

Catering to a wide range of applications, the Grooved Rigid Coupling is available in sizes from 1 inch to 12 inches in diameter.Rated for a working pressure of up to 300 PSI, it meets the demands of various high-pressure applications.The coupling is FM approved and UL certified, ensuring it meets the highest standards of safety and quality.To suit different environmental conditions, it comes in various coatings including red painted, galvanized, epoxy blue, and grey.The coupling features gaskets made from EPDM, NITRILE, or SILICON, providing excellent sealing properties and compatibility with various fluids.

Construction and Functionality:

Applications of Grooved Rigid Couplings

- HVAC and Plumbing Systems: Ensures a secure and leak-resistant connection in heating, ventilation, air conditioning, and plumbing installations.

- Fire Protection and Suppression Systems: Provides a reliable joint in fire suppression pipelines, crucial for safety.

- Water Treatment Facilities: Suitable for the demanding environments of water treatment and distribution systems.

- Oil and Gas Pipelines: Offers a robust solution for the transport of oil and gas.

- Chemical Processing Plants: Ensures a tight seal in pipelines carrying aggressive chemicals.

- Marine and Offshore Installations: Designed to withstand the harsh conditions of marine and offshore environments.

Advantages Grooved Rigid Couplings

The design of the Grooved Rigid Coupling is focused on swift and effortless assembly, which substantially diminishes the time and expense associated with labor. Its meticulously crafted grooves fit seamlessly with the pipe ends’ grooves to form a secure and trustworthy connection. This coupling offers a flexible and steadfast method for connecting pipes, delivering exceptional efficiency across a diverse array of applications.

JANZHI-Malleable iron pipe fittings

EN10226 /ASMEB1.20.1/IS0228/IS07-1

Protect pipe fittings from injury during connection

disrupting their original performance

please contact our staff

0.6MPa

standard

0.5MPa

±0.3°

standard

+0.5°

363MPa

standard

330MPa

12%

standard

8%

100% individuoltesting ofthe product

Reduce carbon emissions and

use renewable energy

Focuson sustainable development

Start from 1982

Sam floot space

Tons of production per year

Tons nbentory

|

Galvanization – Threading – Detail processing – Grinding

government group

government group

Sold to over 30

countries and regions

JANZHI Group holds 13.6% market share

Gas Pipeline System holds 60% market share

customized needs of different customers

after-sales service and technical support

Customer Service