Product Description

Wholesale Pipe End Caps Round from top malleable iron pipe fittings manufacturer with factory price.

The pipe cap is a pipe fitting welded on the pipe end or installed on the external thread of the pipe end to cover the pipe. It is used to close the pipeline and has the same function as the pipe plug.

Pipe caps are not very common in industrial buildings, because pipe caps are only used at the end of the pipe to close the pipe.

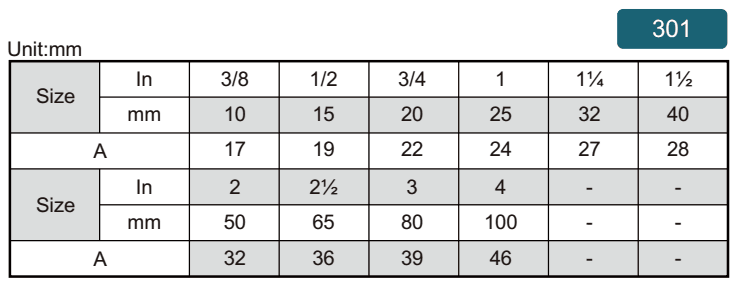

This 301 galvanized round cap is made of malleable iron, Malleable cast iron has good plasticity and tensile strength, and its price is economical, and with galvanized surface treatment, it has good Rust and corrosion resistance, can be widely used in water or liquid conveyor system. The size range is fully covered from 3/8” to 4”.

Round caps are more popular than octagonal caps in industrial fields.

Do you know?

Due to the new Disa Lines imported from Danmark, our production capacity catch 40,000tons per year. The top 1 in China.

The new machine make we can finish every order in 35 days.

How to cap galvanized pipe?

Capping galvanized pipe is a straightforward process that involves sealing the end of the pipe to prevent leaks and protect against corrosion. To begin, ensure you have the right materials, including a galvanized pipe cap that matches the diameter of your pipe and a pipe wrench or adjustable pliers. First, clean the end of the pipe to remove any dirt, debris, or rust, as this will help create a better seal. If necessary, use a wire brush to smooth the surface. Then, simply place the cap over the end of the pipe and tighten it securely with the wrench or pliers, ensuring it is snug but not overly tight to avoid damaging the threads.

After capping the pipe, it’s essential to check for any leaks. Turn on the water supply (if applicable) and inspect the connection for any signs of moisture. If there are no leaks, the cap is properly secured. For added protection against corrosion, especially in outdoor or damp environments, consider applying a coat of galvanized pipe paint or a sealant around the edges of the cap. This extra step can help extend the lifespan of the capped pipe and maintain its integrity over time.

Product Parameters

Product Dimensions

Technical Data

JANZHI-Malleable iron pipe fittings

EN10226 /ASMEB1.20.1/IS0228/IS07-1

Protect pipe fittings from injury during connection

disrupting their original performance

please contact our staff

0.6MPa

standard

0.5MPa

±0.3°

standard

+0.5°

363MPa

standard

330MPa

12%

standard

8%

100% individuoltesting ofthe product

Reduce carbon emissions and

use renewable energy

Focuson sustainable development

Start from 1982

Sam floot space

Tons of production per year

Tons nbentory

|

Galvanization – Threading – Detail processing – Grinding

government group

government group

Sold to over 30

countries and regions

JANZHI Group holds 13.6% market share

Gas Pipeline System holds 60% market share

customized needs of different customers

after-sales service and technical support

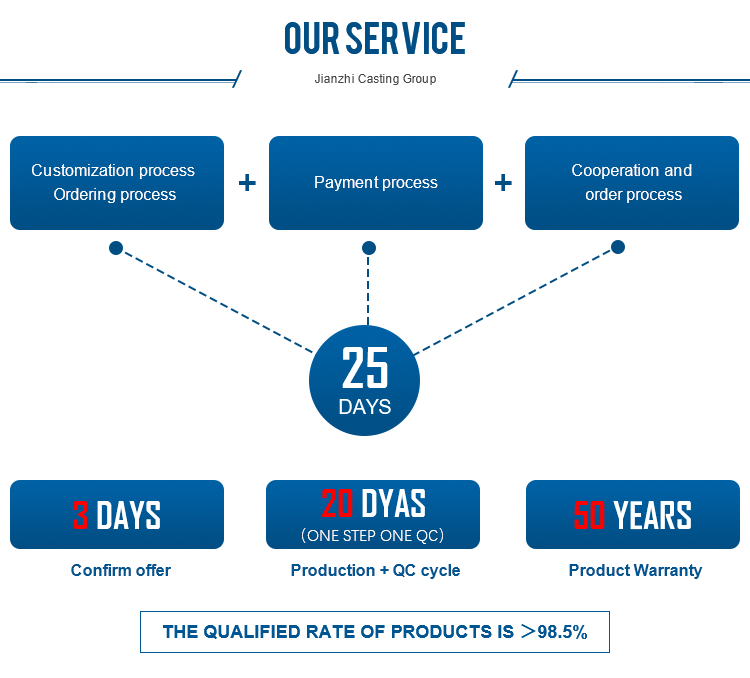

Customer Service