Product Description

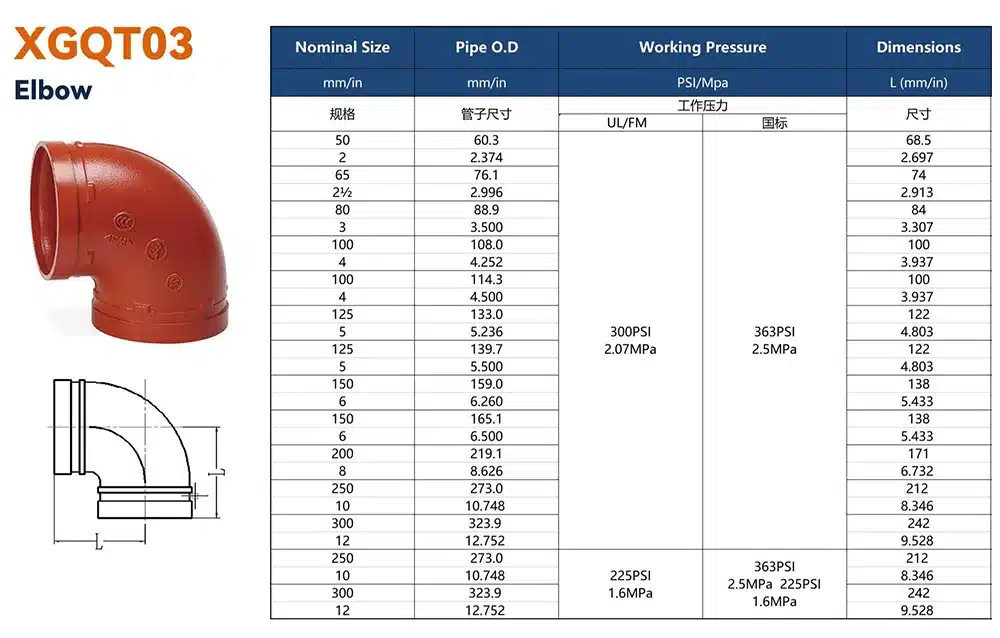

90 Degree Grooved Elbow is a highly engineered fitting designed to facilitate a 90-degree directional change in piping systems. Its grooved ends ensure secure and efficient connections to grooved pipes, providing a leak-free transition around corners or bends. This fitting is essential for efficient routing of piping systems while maintaining optimal flow characteristics.

Advantages of the 90 Degree Grooved Elbow

Versatile Applications Across Industries

- HVAC and Plumbing Systems: Ideal for commercial and residential buildings, ensuring efficient fluid transport and system integrity.

- Fire Protection and Suppression Systems: Crucial for the safety of industrial facilities and high-rise structures.

- Water Treatment Plants: Suitable for municipal infrastructure projects, ensuring safe and efficient water transport.

- Industrial Piping Networks: A reliable solution for chemical processing, oil and gas, and manufacturing facilities, where precise directional changes are necessary.

JANZHI-Malleable iron pipe fittings

EN10226 /ASMEB1.20.1/IS0228/IS07-1

Protect pipe fittings from injury during connection

disrupting their original performance

please contact our staff

0.6MPa

standard

0.5MPa

±0.3°

standard

+0.5°

363MPa

standard

330MPa

12%

standard

8%

100% individuoltesting ofthe product

Reduce carbon emissions and

use renewable energy

Focuson sustainable development

Start from 1982

Sam floot space

Tons of production per year

Tons nbentory

|

Galvanization – Threading – Detail processing – Grinding

government group

government group

Sold to over 30

countries and regions

JANZHI Group holds 13.6% market share

Gas Pipeline System holds 60% market share

customized needs of different customers

after-sales service and technical support

Customer Service