When shopping for pipes, we often see numbers like 1/8 bend in degrees, 90 degree Bend Pipe, and 180 Degree Return Bend. What do these numbers mean, and how do we choose?

Elbows play a vital role in pipeline systems. They change the direction of the pipeline, affect the overall performance of the pipeline system.

The main role of elbows in pipeline systems:

1.Change of fluid flow direction:

Elbows can effectively guide the fluid to flow along a predetermined path.

2.Fluid flow resistance:

The presence of elbows will increase the resistance to fluid flow. Because the fluid will change its flow velocity and direction at the bend. This resistance may cause an increase in pressure loss in the pipeline system. Especially in fluids with high flow velocity or high viscosity.

When designing a pipeline system, it is necessary to consider the number and position of elbows. It balance the flow resistance of the fluid and the efficiency of the system.

3.Pressure distribution and stress:

The change in the shape of the elbow part will cause a change in the pressure distribution inside the pipeline. At the bend, pressure concentration or increased stress may occur. The selection of elbows needs to take into account the pressure bearing capacity to ensure the safety and stability of the pipeline system.

Larger bending angle of the elbow , smaller impact on the pressure. The pressure loss will be reduced accordingly. At the same time, the number of elbows is also a key factor affecting the pressure distribution of the pipeline. In a certain length of pipeline, the more elbows there are, the greater the total resistance of the pipeline, and the pressure loss will increase accordingly.

Before the fluid enters the elbow, the pressure distribution is almost uniform. However, after the fluid enters the elbow, a large pressure gradient will be formed, and the pressure on the outer bend wall is the highest. This will affect the strength and sealing of the pipeline, especially in the case of long-term operation and erosion wear.

Therefore, choosing a suitable elbow can improve the service life and safety of the entire pipeline system.

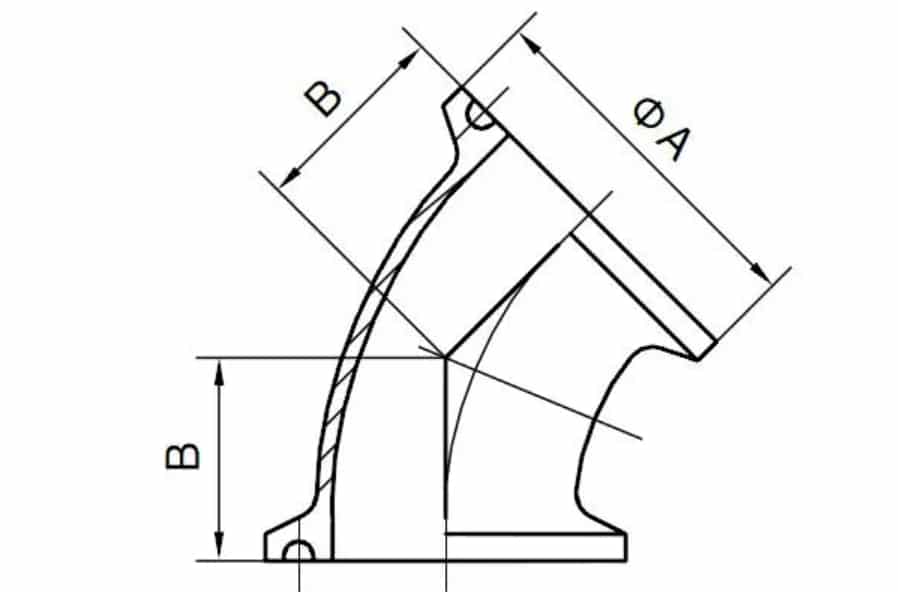

The main functions of 45 degrees(1/8 bend in degrees) :

Changing flow direction: In situations where the fluid needs to be deflected 45 degrees in the pipeline, the 45-degree elbow is a very practical component.

Reduce flow resistance: Compared with 90-degree or 180-degree elbows, the flow resistance caused by 45-degree elbows is relatively small, which is conducive to maintaining the flow speed and pressure of the fluid.

Adapt to layout: In complex pipeline layouts, 45-degree elbows can more flexibly adapt to pipeline connection requirements in different directions.

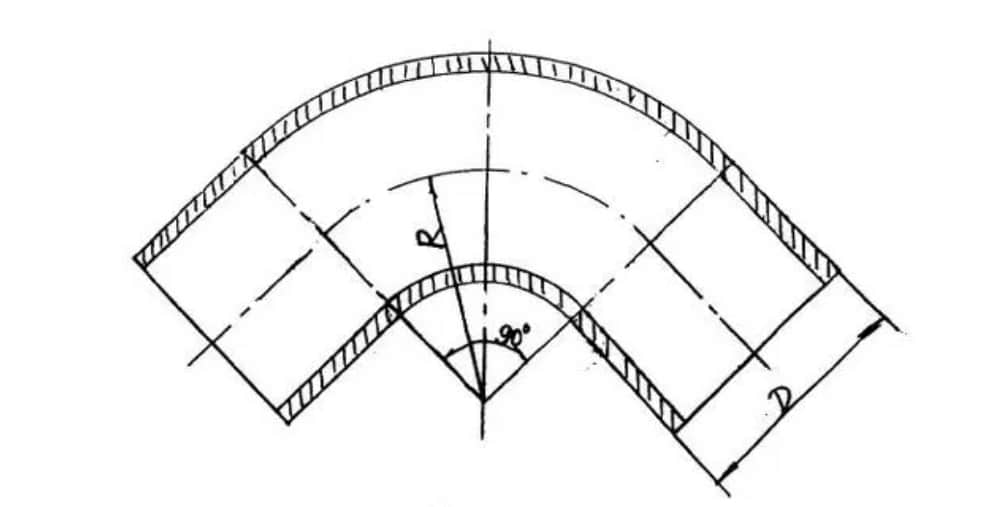

The main functions of 90-degree Bend Pipe:

Change the direction of fluid flow: The most basic function is to enable the fluid to achieve a 90-degree direction change in the pipeline.

Connect pipes in different directions: In a complex pipeline system, pipes connected in different directions. Our BSP Black Malleable Iron 90 Degree Bend Fig. 2 can easily connect these pipes in different directions to ensure the connectivity and integrity of the entire pipeline system.

Improve the flexibility of pipeline layout: By using 90-degree elbows, designers can arrange pipes more flexibly and better adapt to the structural and spatial requirements of the building.

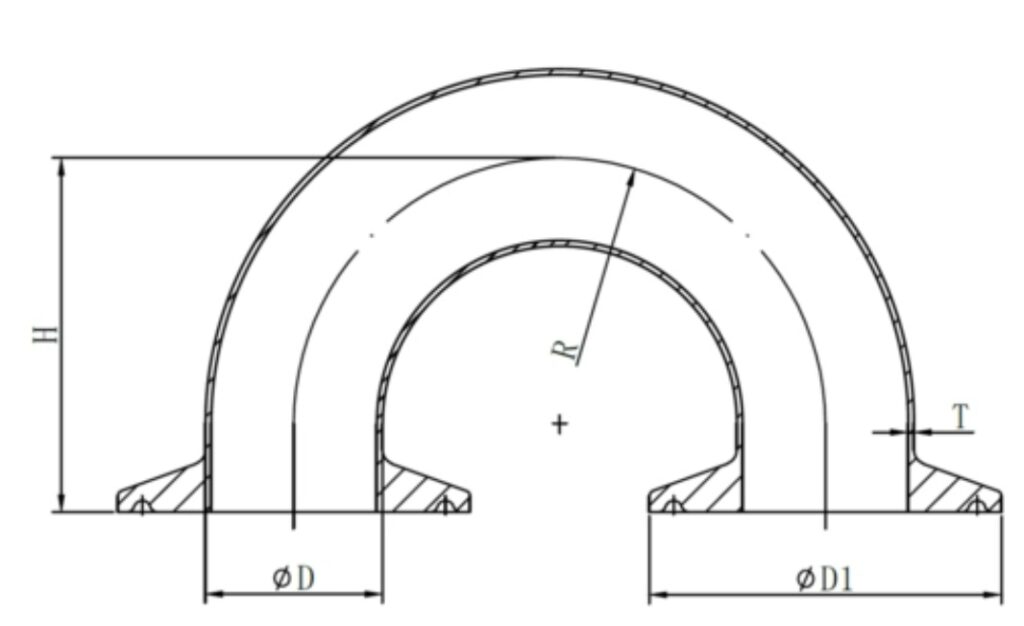

The main functions of 180 Degree Return Bend Fig.90U:

Fluid flow reversal: The core function of the 180-degree return bend is to enable the fluid to achieve a 180-degree direction reversal in the pipeline. This is very critical in certain specific pipeline layout and connection scenarios.

Space optimization and layout: In some space-constrained or complex pipeline systems, 180-degree return bends can optimize the layout of the pipeline, reduce the required pipeline length and the number of joints. It helps to reduce material costs, simplify the installation process, and improve construction efficiency.

Relieve pipeline stress: Pipes may be stressed due to gravity, pressure or other external factors. By introducing a 180-degree return bend, these stresses can be alleviated to a certain extent and the stability and reliability of the pipeline system can be improved.