Product Description

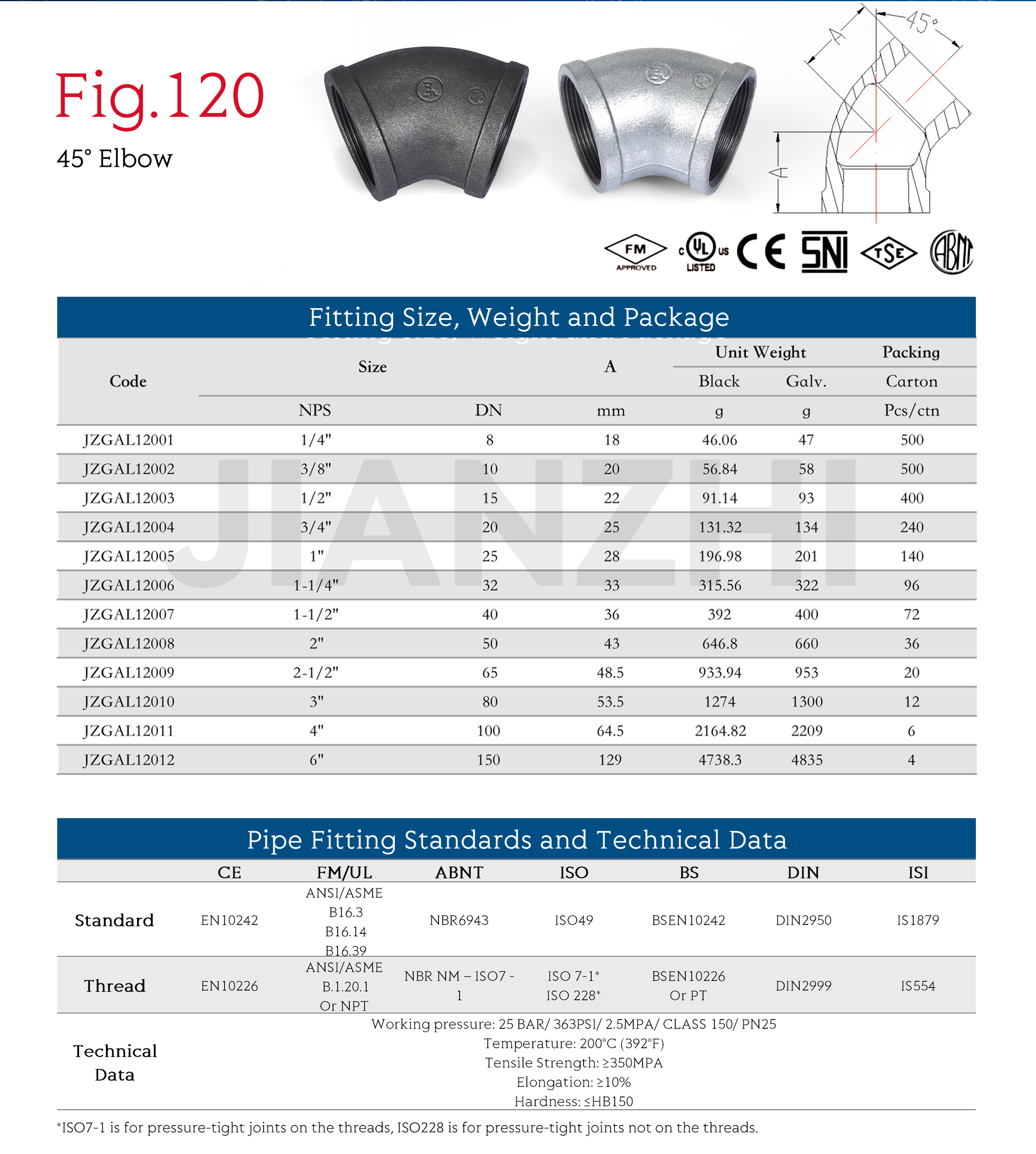

Technical Data:

- Maximum Pressure: 25 BAR (363 PSI) (2.5 MPa) CLASS 150

- Maximum Temperature: 200°C (392°F)

- Tensile Strength: 350 MPa

- Hardness: HB150 (Brinell)

- Elongation Rate: 10%

- Suitable Applications: Water, Oil, Gas, Petrochemical

- Material: Malleable Iron

In a black iron pipe elbow piping system, the elbow is a fitting that changes the direction of the pipeline. The most commonly used angles are 45°, 90°, and 180°. Additionally, for specific engineering needs, there are elbows with unusual angles such as 60°. Elbows can be made from various materials including cast iron, stainless steel, alloy steel, malleable cast iron, carbon steel, non-ferrous metals, and plastics. Connection methods include direct welding (the most common), flange connection, hot melt connection, electrofusion connection, threaded connection, and socket connection. Based on the production process, elbows can be categorized into welding elbows, stamping elbows, push elbows, and casting elbows.

The elbows produced by Jianzhi Pipe Fittings are of good quality and have passed many international certifications, such as CE, FM, UL, etc. The products contain two specifications of NPT and BSPT threads.

JANZHI-Malleable iron pipe fittings

EN10226 /ASMEB1.20.1/IS0228/IS07-1

Protect pipe fittings from injury during connection

disrupting their original performance

please contact our staff

0.6MPa

standard

0.5MPa

±0.3°

standard

+0.5°

363MPa

standard

330MPa

12%

standard

8%

100% individuoltesting ofthe product

Reduce carbon emissions and

use renewable energy

Focuson sustainable development

Start from 1982

Sam floot space

Tons of production per year

Tons nbentory

|

Galvanization – Threading – Detail processing – Grinding

government group

government group

Sold to over 30

countries and regions

JANZHI Group holds 13.6% market share

Gas Pipeline System holds 60% market share

customized needs of different customers

after-sales service and technical support

Customer Service