Product Description

In water and gas supply systems, a threaded fitting with female thread closes the hole tightly either permanently or temporarily. As a result of the use of cast iron threaded fittings, the whole system in the compartment is protected against accidental leaks, breaks, and depressurization, not only at the connection points but throughout the entire pipeline system. Tips: Fitting size and normal size(DN)

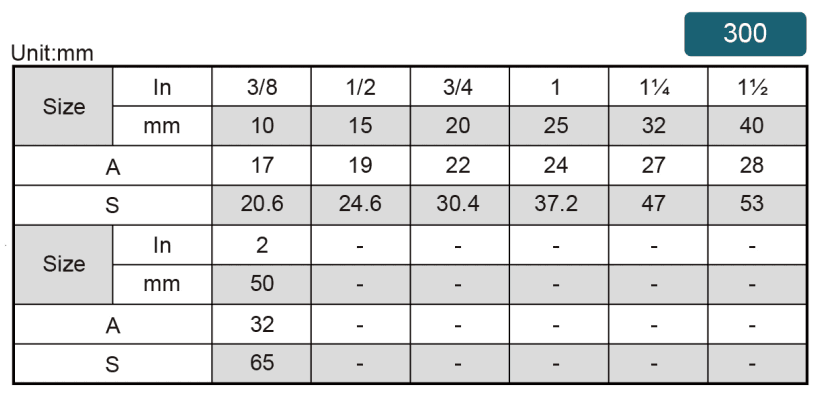

Hexagon cap nut Parameters

Product Dimensions

Technical Data

JANZHI-Malleable iron pipe fittings

EN10226 /ASMEB1.20.1/IS0228/IS07-1

Protect pipe fittings from injury during connection

disrupting their original performance

please contact our staff

0.6MPa

standard

0.5MPa

±0.3°

standard

+0.5°

363MPa

standard

330MPa

12%

standard

8%

100% individuoltesting ofthe product

Reduce carbon emissions and

use renewable energy

Focuson sustainable development

Start from 1982

Sam floot space

Tons of production per year

Tons nbentory

|

Galvanization – Threading – Detail processing – Grinding

government group

government group

Sold to over 30

countries and regions

JANZHI Group holds 13.6% market share

Gas Pipeline System holds 60% market share

customized needs of different customers

after-sales service and technical support

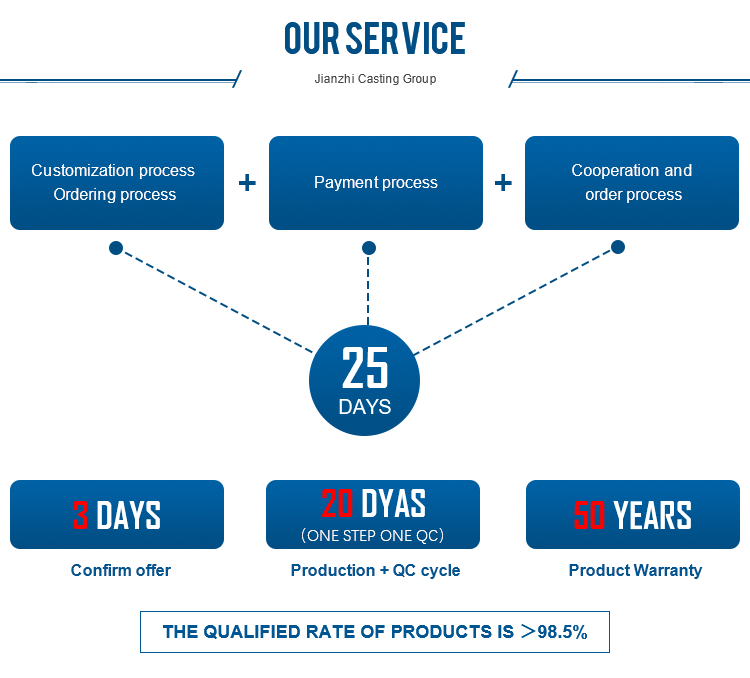

Customer Service