Product Description

reducing nipple for sale

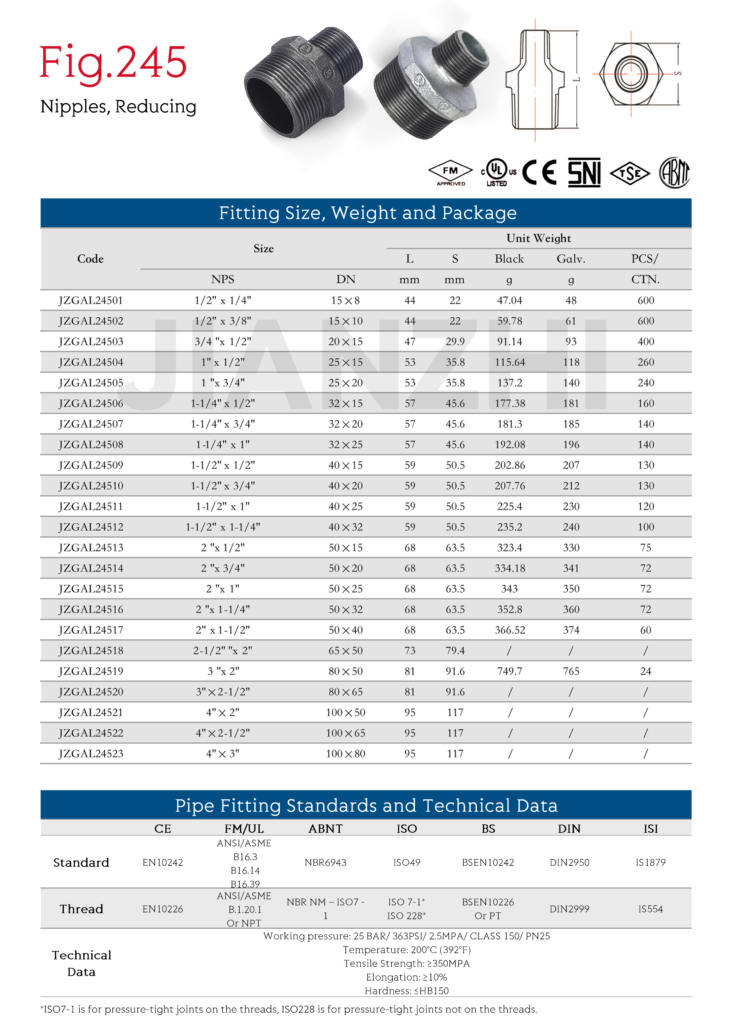

Maximum Pressure: 25 BAR (363PSI) (2.5MPA) CLASS 150

Maximum Temperature: 200°C (392°F)

Tensile Strength: 350MPA

Hardness: HB150 (Brinell)

Elongation Rate: 10%

Suitable Applications: Water, Oil, Gas, Petro-Chemical

Material: Malleable Iron

Do you know?

There is a 0.5 degree change in the axis angle between BSPT (BS EN 10226) and Jianzhi, but only a 0.3 degree change in the axis angle between Jianzhi and BSPT.

Suitable for water and gas environments, cast iron and steel fittings provide a strong and reliable connection. Cast iron and steel fittings provide a strong and reliable metal connection. These fittings can be found in a variety of forms, such as couplings, transitional couplings, locks, crosses, elbows, tees, butts, American women, and nipples, among others. Cast iron and steel fittings are used for different purposes, both outside and indoors, depending on the humidity and temperature. A chemical process known as galvanizing is used to protect products made from steel and iron (fittings) against mechanical damage. Zinc is also almost completely protected from metal oxidation (rust) when applied by hot or galvanized galvanizing.

Reducing Nipples

JANZHI-Malleable iron pipe fittings

EN10226 /ASMEB1.20.1/IS0228/IS07-1

Protect pipe fittings from injury during connection

disrupting their original performance

please contact our staff

0.6MPa

standard

0.5MPa

±0.3°

standard

+0.5°

363MPa

standard

330MPa

12%

standard

8%

100% individuoltesting ofthe product

Reduce carbon emissions and

use renewable energy

Focuson sustainable development

Start from 1982

Sam floot space

Tons of production per year

Tons nbentory

|

Galvanization – Threading – Detail processing – Grinding

government group

government group

Sold to over 30

countries and regions

JANZHI Group holds 13.6% market share

Gas Pipeline System holds 60% market share

customized needs of different customers

after-sales service and technical support

Customer Service