Product Description

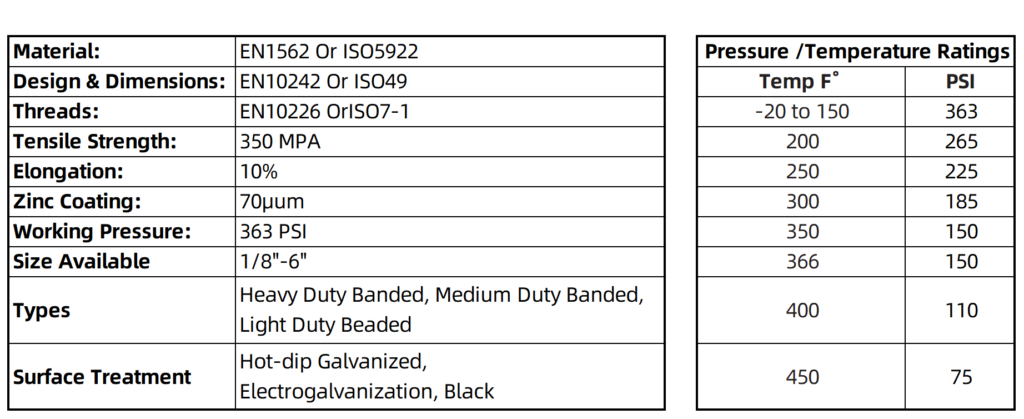

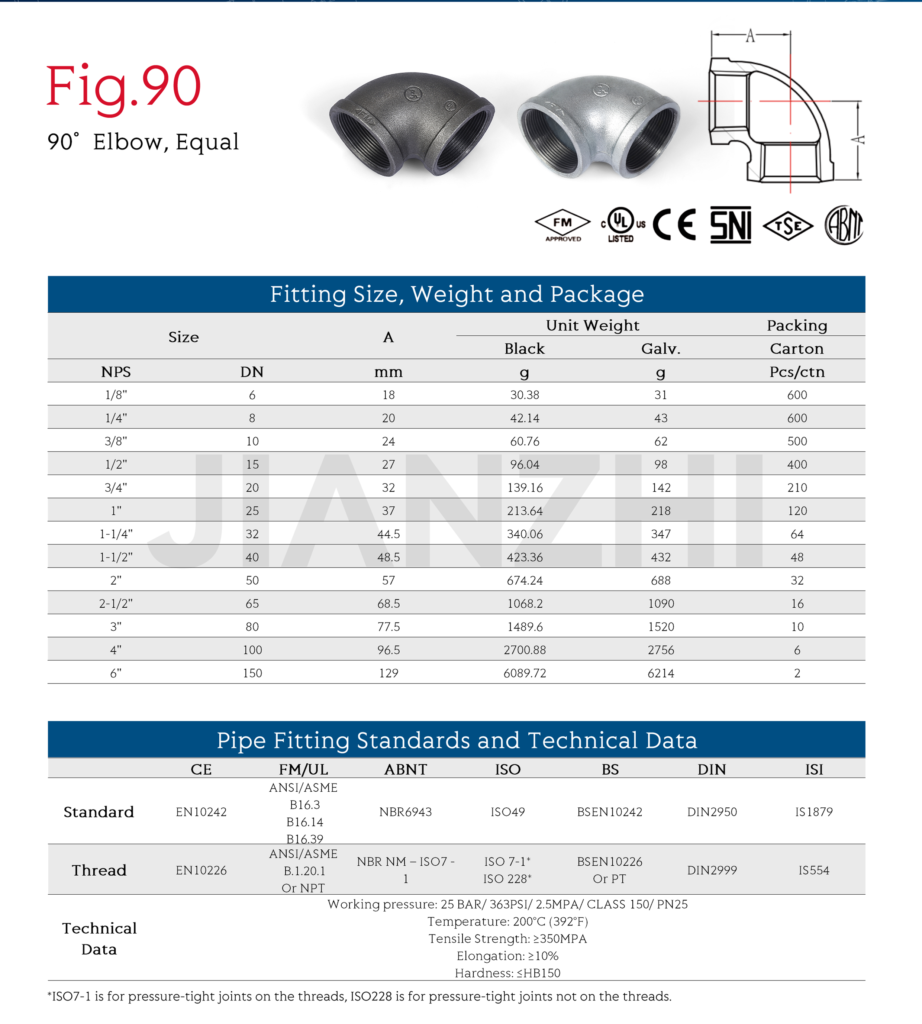

Standards and Technical Data:

Product Detailed Size:

JIANZHI has more than 40 years of casting experience and technical reserve. The annealing process is a key process in the production of malleable iron.

in the annealing process, in order to ensure all fittings quality, JIANZHI adopts tunnel annealing furnaces. You may find thread cracking in some other brand products, this is a sign of immature annealing technology. If you find one unqualified product, including thread breaking, JIANZHI will pay you 200RMB. If you find an air hole product, you will get a 500RMB payment. when you find a grey product, we will pay you 1688RMB. So far, no manufacturer dares to make the above quality promise. JIANZHI has the confidence to make this promise because of strict quality control. Choose JIANZHI, let JIANZHI bring you more benefits.

Related Other Pipe Fittings:

JANZHI-Malleable iron pipe fittings

EN10226 /ASMEB1.20.1/IS0228/IS07-1

Protect pipe fittings from injury during connection

disrupting their original performance

please contact our staff

0.6MPa

standard

0.5MPa

±0.3°

standard

+0.5°

363MPa

standard

330MPa

12%

standard

8%

100% individuoltesting ofthe product

Reduce carbon emissions and

use renewable energy

Focuson sustainable development

Start from 1982

Sam floot space

Tons of production per year

Tons nbentory

|

Galvanization – Threading – Detail processing – Grinding

government group

government group

Sold to over 30

countries and regions

JANZHI Group holds 13.6% market share

Gas Pipeline System holds 60% market share

customized needs of different customers

after-sales service and technical support

Customer Service