Malleable cast iron threaded pipe fittings are usually used to connect threaded steel pipes. According to different produce standard, there are different thread standards, such as NPT, BSP, G and so on. The common surface treatments are black or galvanized, and the galvanized malleable cast iron pipe fittings are used for galvanized pipes. Zinc layer prevents malleable iron fittings from rusting and prolongs their service life.

Malleable cast iron is cast as white iron, the structure being a metastable carbide in a pearlitic matrix. Through an annealing heat treatment, the brittle structure as the first cast is transformed into the malleable form. It is often used for small castings requiring good tensile strength and the ability to flex without breaking (ductility). The pipe fittings are produced by malleable cast iron, we called them malleable cast iron pipe fittings.

There are many different types of malleable pipe fittings.

Malleable Iron Pipe Fittings Materials

From 1720 to 1722 AD, the French Reaumur invented the white-hearted malleable iron production method, which was later commonly referred to as the “European method”. In 1982, American Seth Boyden decomposed Fe3C in white cast iron through accidental heat treatment, so that flocculent graphite + metal matrix was precipitated. The malleable iron he obtained at that time had a ferritic matrix. This method is commonly referred to as the “American Method” black-hearted malleable iron.

The black-heart malleable iron is developed from the white-heart malleable iron process, and the matrix is ferrite + flocculent graphite structure. At present, 90% of the malleable iron produced in China is black-heart malleable iron. Because the carbon exists in the form of flocculent graphite, it has good strength, high plasticity and toughness. Now Jianzhi’s malleable pipe fittings are made of black-heart malleable iron.

Manufacturing process

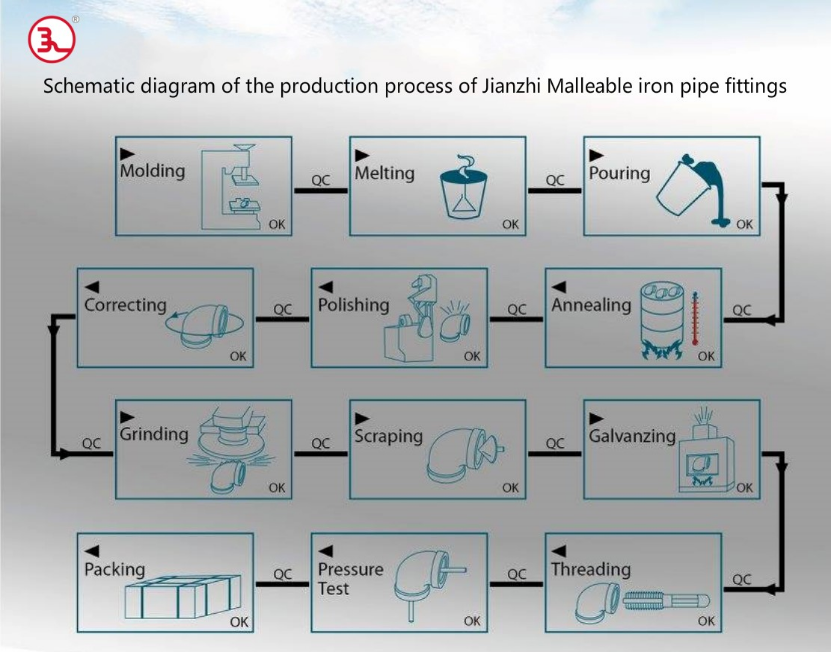

Malleable iron fittings are made using the most sophisticated metallurgical and processing controls. These fittings are usually made through casting and an automatic precision pattern extrusion. There are 10 main production processes included (figure 1).

In these 10 production processes, annealing is a very important link. Annealing is a metal heat treatment process, which refers to slowly heating the metal to a certain temperature, holding it for a sufficient time, and then cooling it at a suitable rate. The purpose is to reduce hardness, improve machinability; eliminate residual stress, stabilize size, reduce deformation and crack tendency; refine grains, adjust organization, and eliminate organizational defects.

Jianzhi Group has 35 years of casting experience and technical reserves, and has the strongest technical ability in the annealing process. At the same time, we use the international advanced tunnel annealing furnace, which effectively guarantees the product performance of the castings.

Buyer’s consideration

The manufacturer’s name or trademark must be there on the malleable cast iron pipe fittings.

The manufacturer’s ability is very important. For example:

- Are the produce the pipe fittings by themselves or OEM from another factory?

- How many employees in their factory?

- How long is the delivery time and whether they can delivery on time?

- Do they have internal certifications? How many?

- Any after-sales service for project customers?

- The most important, whether they can provide you a business proposal to help wholesalers or stockiest sell the products?

Applications

Malleable iron pipe fittings are used in various applications of the pipeline system, like steam, air, water, gas, oil and other fluids.

Users can choose galvanized pipe fittings or black pipe fittings according to their own needs for rust prevention.

Types of malleable cast iron pipe fittings

There are various pipe fittings that are made of malleable cast iron materials. Some of the common malleable iron pipe fittings are:

The video below will show you more pipe fittings:

Thread types and detection methods

The castings before the threading process are called blanks. Some customers, due to the requirements of the country or region, also directly purchase the blanks from our company, and perform threading processing according to the requirements in the country, so as to meet some special use requirements of the country or meet the requirements of the country of origin.

- Threading refers to machining the blanks according to the customer’s requirements and machining threads of different national standards on the castings according to the customer’s requirements. Pipe threads mainly include the following: NPT, PT, G, etc.

- NPT is the abbreviation of National (American) Pipe Thread, which belongs to the American standard 60-degree tapered pipe thread, mainly used in North America.

- PT (BSPT) is the abbreviation of Pipe Thread. This is a conical pipe thread with a 55-degree seal. It belongs to the Wyeth thread family. In the water and gas pipe industry, it is mostly used in Europe and the Commonwealth of Nations.

- G is a 55-degree unsealed pipe thread, which belongs to the Whitworth thread family. Marked as G stands for cylindrical thread.

•Test the angle of the thread axis to judge the accuracy of the pipe thread.

There are two ways to test the angle of the thread axis.

- Test rod measurement

- Goniometer detection

The principle of the two methods is the same, but the detection equipment and methods are different. The Chinese standard stipulates that the deviation of the pipe thread angle should not exceed ±0.5°, and the jianzhi pipe fittings should be controlled within ±0.3°, which is 40% stricter than the national standard.

This article introduces the problems related to the testing of malleable pipe fittings.

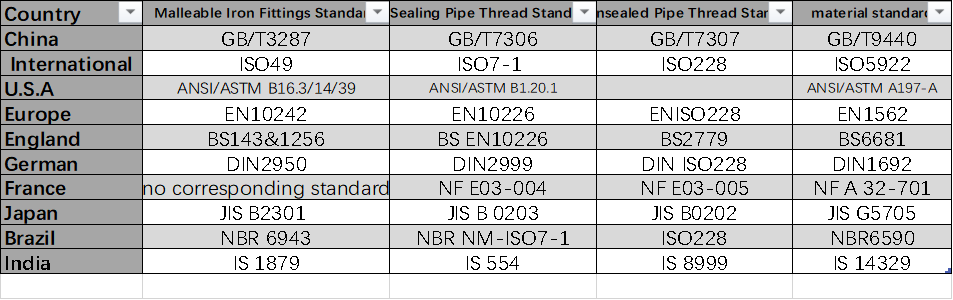

Pipe fitting product standards in different countries

I believe that when you see here, you have a comprehensive understanding of malleable steel pipe fittings. If you want to know more, you can contact us through the email address on the website, and our salesman will give you a more professional answer.